Exploring the Advantages of Fiber Laser Enclosures for Enhanced Safety and Efficiency in Manufacturing

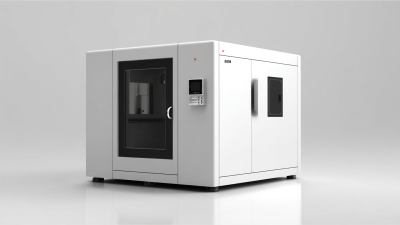

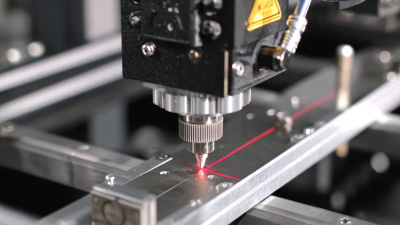

In recent years, the adoption of fiber lasers in manufacturing has surged, primarily due to their efficiency and precision. A critical component in leveraging the full potential of fiber lasers is the implementation of a Fiber Laser Enclosure, which not only enhances safety but also boosts operational efficiency.

According to a report by the International Organization for Standardization (ISO), workplaces that incorporate laser safety enclosures have seen a 30% reduction in accident rates, significantly improving employee safety and compliance with regulatory standards. Additionally, a study published in the Journal of Manufacturing Science and Engineering indicated that fiber laser systems enclosed appropriately can achieve up to a 20% improvement in processing speed, as they minimize interruptions caused by environmental factors. By exploring the multifaceted advantages of Fiber Laser Enclosures, manufacturers can ensure that they are not only protecting their workforce but also maximizing productivity and output quality in their operations.

Benefits of Fiber Laser Enclosures in Reducing Workplace Accidents in Manufacturing

Fiber laser enclosures play a critical role in enhancing safety within the manufacturing environment. By effectively containing laser operations, these enclosures minimize the risk of unintentional exposure to harmful laser emissions. This containment is essential not only for protecting workers from potential eye injuries but also for mitigating the dangers of ignition or burns from laser materials. The design of fiber laser enclosures often incorporates safety interlocks and reinforced materials, providing an additional layer of protection that ensures operators can work without the constant fear of accidents.

Fiber laser enclosures play a critical role in enhancing safety within the manufacturing environment. By effectively containing laser operations, these enclosures minimize the risk of unintentional exposure to harmful laser emissions. This containment is essential not only for protecting workers from potential eye injuries but also for mitigating the dangers of ignition or burns from laser materials. The design of fiber laser enclosures often incorporates safety interlocks and reinforced materials, providing an additional layer of protection that ensures operators can work without the constant fear of accidents.

Moreover, the implementation of fiber laser enclosures contributes to a more focused and efficient manufacturing process. By isolating the laser operation from the surrounding environment, distractions are reduced, allowing workers to concentrate on their tasks. This heightened focus not only promotes a safer work atmosphere but also improves overall productivity. Reduced noise levels within the enclosure further enhance this efficiency, creating a more pleasant work experience. In essence, fiber laser enclosures serve as a dual-purpose solution, fostering both enhanced safety and operational efficiency in manufacturing settings.

Impact of Fiber Laser Enclosures on Operational Efficiency and Productivity Metrics

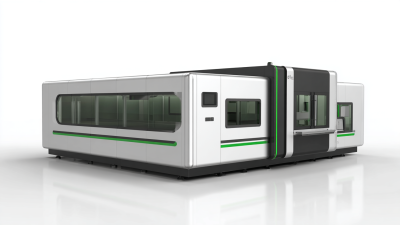

Fiber laser enclosures play a pivotal role in enhancing operational efficiency and productivity metrics in manufacturing environments. By providing a controlled atmosphere, these enclosures not only protect operators from hazardous laser exposure but also minimize disruptions caused by external factors, such as dust and environmental fluctuations. This controlled environment contributes to a more reliable operating process, reducing the likelihood of faults and failures that can lead to downtime. Consequently, manufacturers experience a notable increase in productivity as equipment runs more consistently and requires less maintenance.

Moreover, the integration of fiber laser enclosures facilitates streamlined workflows and improved safety protocols. With reduced noise levels and a designated workspace, employees can focus better on their tasks, leading to higher accuracy and quality in production. Enhanced visibility of the cutting or engraving processes within the enclosure allows for real-time monitoring, enabling quick adjustments and immediate responses to any operational hiccups. As a result, the overall throughput of the manufacturing line is significantly boosted, demonstrating that fiber laser enclosures are not only a safety feature but also a crucial component for driving operational excellence.

Impact of Fiber Laser Enclosures on Operational Efficiency and Productivity Metrics

Regulatory Compliance: How Enclosures Enhance Safety Standards in Laser Operations

In the realm of laser manufacturing, compliance with safety regulations is paramount. Enclosures for fiber lasers play a pivotal role in enhancing safety standards. According to a report by the Laser Institute of America, laser-related injuries can significantly decrease when appropriate safety measures, including enclosures, are implemented. These enclosures not only provide a physical barrier that minimizes exposure to harmful laser emissions but also aid in containing hazardous fumes and particles generated during cutting or engraving processes. The Occupational Safety and Health Administration (OSHA) highlights that maintaining a safe work environment can reduce workplace accidents by up to 50%, emphasizing the critical function of enclosures.

Tips: Regularly inspect and maintain laser enclosures to ensure they are free from damage and functioning correctly. Implement a clear maintenance schedule, and educate employees on proper usage to maximize safety.

The design of fiber laser enclosures must also adhere to specific regulatory standards, such as those set forth by ANSI Z136.1, which outlines the safe use of lasers in various environments. Compliance not only protects workers but can also enhance productivity by preventing downtime due to safety incidents. A study from the National Institute for Occupational Safety and Health (NIOSH) indicated that companies prioritizing safety compliance experience a 33% boost in operational efficiency.

Tips: Invest in training programs to familiarize operators with safety standards and the importance of enclosures. Continuous education can significantly raise awareness and contribute to a consistently safe workplace.

Economic Advantages: Cost-Benefit Analysis of Implementing Fiber Laser Enclosures

Fiber laser enclosures have become an essential component in modern manufacturing, offering not only enhanced safety but also significant economic advantages. According to industry reports, the implementation of fiber laser enclosures can reduce operational costs by up to 30% due to minimized material waste and increased energy efficiency. By integrating these enclosures, manufacturers are able to achieve a more controlled environment, which helps in maintaining consistent production quality.

The economic benefits are further evidenced by a cost-benefit analysis that reveals a potential return on investment (ROI) exceeding 150% within the first year of installation. As seen in the evolution of EV battery enclosures, balancing safety, efficiency, and cost-effectiveness is crucial. The advancements in enclosure technology have led to decreased manufacturing errors and injuries, aligning with increasing regulatory standards. As companies continue to optimize their operations, fiber laser enclosures represent a strategic investment that aligns with both safety protocols and overall productivity enhancements in the competitive manufacturing landscape.

Innovative Technologies: Latest Trends in Fiber Laser Enclosure Design and Safety Features

The design of fiber laser enclosures is evolving rapidly, driven by innovative technologies aimed at enhancing both safety and efficiency in manufacturing environments. Recent trends highlight the integration of advanced materials that not only improve durability but also provide better acoustic insulation. For instance, manufacturers are increasingly using composite materials that withstand high temperatures while ensuring minimal noise pollution. This shift not only protects workers from harmful exposure but also contributes to a more pleasant working environment.

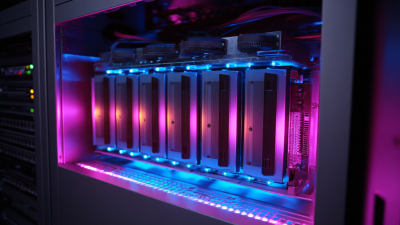

Safety features in modern fiber laser enclosures are also becoming more sophisticated. Automated systems for real-time monitoring are being implemented, allowing for immediate alerts in case of any anomalies. Another noteworthy trend is the incorporation of smart technology that enables remote diagnostics and control, facilitating proactive maintenance and reducing downtime. These advancements are essential in minimizing operational risks, ultimately leading to increased productivity and safety in manufacturing settings. The combination of cutting-edge design and robust safety features is setting new standards for the fiber laser industry.

Exploring the Advantages of Fiber Laser Enclosures for Enhanced Safety and Efficiency in Manufacturing

| Feature | Description | Advantages | Applications |

|---|---|---|---|

| Safety Interlocks | Automatic shutdown mechanism when doors are opened | Reduces risk of accidents | Manufacturing, metal cutting |

| Noise Reduction | Insulated enclosure to minimize sound levels | Improved working environment | Industrial workplaces |

| Dust and Fume Containment | Enclosure prevents the escape of harmful particles | Enhances air quality | Welding, laser cutting |

| Temperature Control | Climate-controlled environments to maintain optimal working conditions | Increases equipment longevity | Electronics manufacturing |

| Modular Design | Flexible configurations to accommodate different setups | Customizable for various applications | Various industrial applications |

Related Posts

-

7 Essential Tips for Choosing the Best Fiber Laser Enclosure for Your Business Needs

-

Ultimate Guide to Choosing the Best Fiber Laser Enclosure for Optimal Safety and Efficiency

-

How to Choose the Right Fiber Laser Enclosure for Your Business Needs

-

How to Choose the Best Fiber Laser Marking Machine for Your Business Needs

-

Understanding Export Compliance for Desktop Fiber Laser Marking Machines in Global Markets

-

Unlocking Precision and Efficiency with Advanced Desktop Fiber Laser Marking Solutions