5 Key Advantages of Using Laser Part Marking Machines for Global Procurement

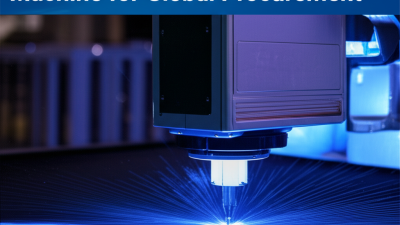

In the rapidly evolving landscape of global procurement, efficiency and precision are paramount for manufacturers striving to maintain a competitive edge. One of the most transformative advancements in this sector is the introduction of the Laser Part Marking Machine. This innovative technology not only enhances product traceability but also significantly reduces processing times and costs associated with traditional marking methods. By leveraging the unparalleled accuracy and durability of laser marking, businesses can streamline their supply chain operations while ensuring compliance with regulatory requirements. In this blog, we will explore the five key advantages of using Laser Part Marking Machines, highlighting how they can redefine procurement strategies and drive operational excellence for companies worldwide.

Key Benefit: Increased Precision and Accuracy in Part Marking

Laser part marking machines have revolutionized the way manufacturers approach labeling and marking components. One of the standout features of these machines is their unparalleled precision and accuracy. Unlike traditional marking methods, laser marking utilizes focused beams of light that can precisely engrave or etch characters and designs onto a variety of materials. This technology ensures that even the most intricate designs remain clear and legible, which is crucial for compliance with global standards.

When integrating laser part marking into your operations, consider these tips. Firstly, ensure that the materials you are marking are compatible with laser technology. Some materials may not produce clear marks or, conversely, may be damaged by the laser. Secondly, routinely maintain your laser equipment to sustain optimal performance and avoid any downtime in your production line. Regular checks can help eliminate inconsistencies in marking quality and ensure that every part meets the required standards.

The result of increased precision is two-fold: not only does it enhance product quality, but it also boosts customer trust. Accurate part markings facilitate better inventory management and traceability, reducing the likelihood of errors during global procurement. This level of accuracy is essential for industries where safety and compliance are paramount, making laser part marking machines a valuable asset in modern manufacturing processes.

Enhanced Durability of Marks for Long-Lasting Identification

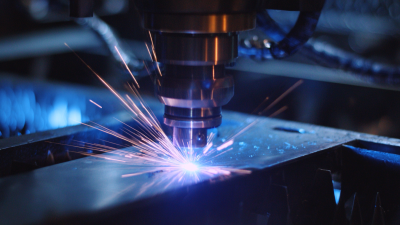

Laser part marking machines are increasingly recognized for their ability to create highly durable marks that withstand various environmental challenges. The advantages of using these machines extend beyond mere identification; they ensure that markings remain intact over time, enhancing the reliability of information traced back to the products. This durability is essential for global procurement, where products often traverse diverse conditions, and the markings need to maintain clarity throughout the supply chain.

Laser part marking machines are increasingly recognized for their ability to create highly durable marks that withstand various environmental challenges. The advantages of using these machines extend beyond mere identification; they ensure that markings remain intact over time, enhancing the reliability of information traced back to the products. This durability is essential for global procurement, where products often traverse diverse conditions, and the markings need to maintain clarity throughout the supply chain.

In addition to their longevity, these laser marking technologies align well with the ongoing trends in sustainable manufacturing practices. Just as the latest advancements in building materials emphasize innovative production technologies, laser marking machines also adopt cutting-edge processing methods that minimize waste and enhance precision. The enhanced durability of the marks not only bolsters identification but also promotes sustainability by reducing the need for frequent re-marking, thereby conserving resources and energy.

As industries increasingly focus on efficiency and sustainability, the adoption of laser part marking machines will likely become a crucial aspect of modern manufacturing and procurement strategies.

Cost-Effectiveness: Reducing Waste and Improving Production Efficiency

The advent of laser part marking machines has revolutionized production efficiency across various industries, particularly concerning cost-effectiveness in global procurement. These advanced machines significantly reduce waste during the marking process. Unlike traditional methods that often involve extensive cleanup and material loss, laser marking is precise and minimizes the excess of raw materials. This efficiency translates into lower operational costs, allowing manufacturers to allocate their resources more effectively.

Furthermore, the integration of laser marking technology enhances overall production efficiency. By streamlining the marking process, manufacturers can increase their output without compromising on quality. This is especially vital in an era where speed and accuracy are paramount for meeting market demands.

With laser marking machines, businesses can improve their workflows, ultimately leading to a more agile and responsive production environment that can adapt to the rapidly changing needs of global procurement. As industries strive for sustainability and effectiveness, the benefits of adopting laser marking technology become increasingly clear.

Versatility of Laser Marking on Diverse Materials

The versatility of laser marking on diverse materials has become a crucial factor in global procurement strategies, especially in the burgeoning market for custom dog tags. As the market for these personalized products is projected to reach $130.4 billion by 2024, with an impressive compound annual growth rate of 7.91% expected to propel it to $260.36 billion by 2033, manufacturers are seeking innovative ways to meet consumer demands while maintaining high-quality standards.

Laser part marking machines offer unmatched flexibility, allowing for precise identification and branding on various substrates, including metals, plastics, and even wood. This adaptability not only enhances product differentiation but also appeals to a wider range of customers looking for unique and personalized options. With the ability to create intricate designs and durable markings that withstand the test of time, laser marking is becoming an essential tool for manufacturers looking to establish a foothold in the competitive custom pet accessory market. The efficiency and precision of laser technology thus play a vital role in driving growth and meeting the diverse needs of consumers worldwide.

Streamlined Compliance with Global Industry Standards and Regulations

The increasing complexity of global procurement requires businesses to adhere strictly to industry standards and regulations. Laser part marking machines are at the forefront of this compliance revolution, offering precise, durable markings that withstand time and environmental factors. According to a recent report by the International Organization for Standardization (ISO), companies utilizing advanced marking technologies are 30% more likely to meet regulatory requirements compared to those using traditional methods. As regulations evolve rapidly, having an adaptable marking solution can significantly mitigate compliance risks.

Tip: Regularly review and update your marking techniques to align with changing regulations. Utilize laser part marking machines that can easily be reprogrammed for updates in compliance standards across different regions.

Moreover, the integration of laser technology in marking processes enhances traceability, a vital aspect for industries such as automotive and pharmaceuticals, where the cost of non-compliance can reach millions. A study from the World Health Organization (WHO) suggests that 45% of product recalls result from labeling errors, highlighting the necessity for reliable marking systems. Laser part marking machines not only provide clear, scannable codes but also offer the ability to mark variable data, ensuring every part is uniquely identified.

Tip: Implement a regular maintenance schedule for your marking machines to ensure optimal performance and longevity. A well-maintained machine will consistently produce quality markings necessary for compliance.

Related Posts

-

Your Ultimate Checklist for Choosing the Best Laser Marking Machine for Global Procurement

-

Challenges in Selecting the Right Laser Part Marking Machinery

-

How to Choose the Right Fiber Marking Machine for Your Business Needs

-

5 Key Insights to Maximize Your Investment in Dot Pin Marking Machines

-

Unleashing Innovations in Laser Part Marking Machines at the Upcoming Canton Fair 2025

-

Ultimate Guide to Choosing the Right Fiber Marking Laser for Your Business Needs