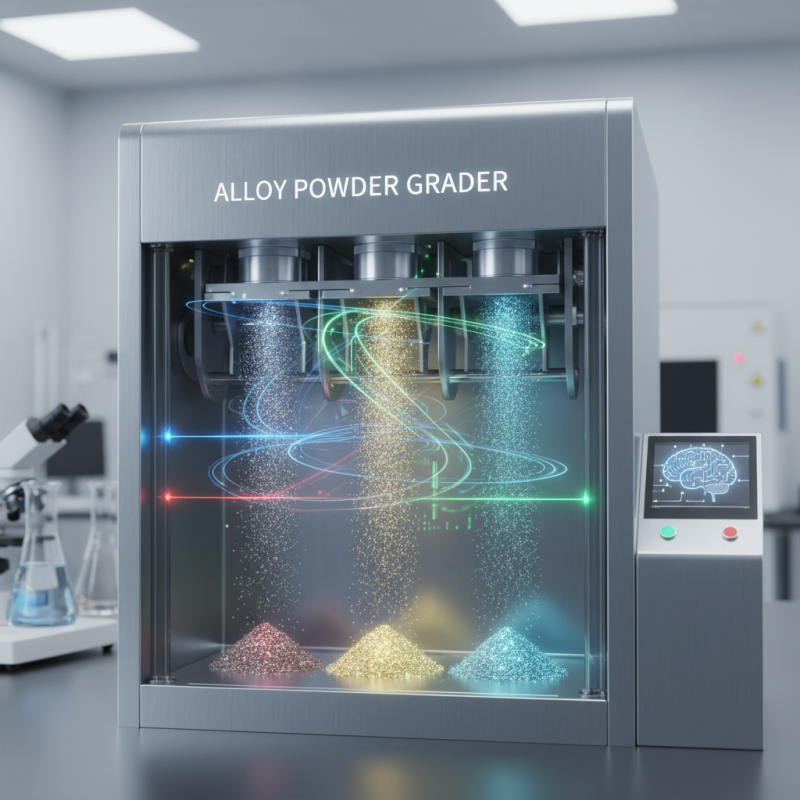

Alloy Powder Grader Tips for Perfect Material Quality?

In the world of metal manufacturing, the quality of alloy powders is crucial. A leading expert in the field, Dr. Thomas Price, once stated, “An efficient Alloy Powder Grader is the heart of consistent material quality.” His insights highlight the importance of precise grading techniques for achieving optimal results.

Alloy Powder Graders play a vital role in ensuring uniformity in powder characteristics. Variations in particle size can lead to serious inconsistencies in end products. Even slight differences can affect the properties of alloys. The challenge lies in accurately assessing these materials. Many industries struggle despite having advanced grading equipment. This reveals a gap between technology and application that needs addressing.

It’s essential to refine grading processes for better outcomes. Nevertheless, the pursuit of perfection often uncovers unexpected issues. Many companies overlook minor variations that can compromise quality. As industry practices evolve, embracing both technology and expert knowledge becomes imperative. Implementing robust grading systems can enhance material consistency significantly.

Alloy Powder Grader Overview: Importance for Material Quality

An alloy powder grader plays a crucial role in determining material quality. These graders ensure uniform particle sizes. This uniformity affects how an alloy behaves in various applications. Inconsistent particle size can lead to issues during production, potentially causing defects in the final product, thus affecting overall performance.

Understanding the grading process is vital. Different methods can yield varying results. For instance, some techniques might overlook finer particles. This oversight can result in a less effective alloy. Moreover, improper calibration of grading machines can compromise accuracy. Regular maintenance is essential to avoid such pitfalls, and timely adjustments ensure that measurements remain within quality standards.

In practice, not every batch will meet expectations. It's normal to face challenges during grading. Operators need to continuously assess techniques. Collecting data on past performances can highlight areas for improvement. By reflecting on these experiences, processes can be refined. Enhanced grading methods can ultimately boost material quality.

Key Factors Influencing Alloy Powder Grading Accuracy

When it comes to alloy powder grading, accuracy is paramount. Several factors can influence this precision. One of the most critical is the particle size distribution. If the powder has a wide range of sizes, the grading may yield inconsistent results. It's essential to regularly check the sieve matrices to ensure proper segregation. This simple step can significantly enhance the quality of your final product.

Another key factor is the moisture content in the alloy powder. High moisture can cause clumping and uneven distribution. This leads to inaccurate grading. It's crucial to keep the storage area dry. Using desiccants can help control humidity. Always monitor the environment to maintain consistent conditions.

Here are a few tips for better grading: employ high-quality sieves to improve separation efficiency. Incorporate laser diffraction methods for precise measurements. Lastly, regularly calibrate your grading equipment. This ensures you maintain an accurate grading process. Remember, even small errors can cascade into larger issues down the line. Assessing your methods can lead to significant improvements.

Step-by-Step Guide to Choosing the Right Alloy Powder Grader

Choosing the right alloy powder grader can be a challenging task. There are various factors to consider before making a decision. First, assess the specific material you are working with. Each type of alloy powder has unique requirements. Understanding these nuances is vital for achieving the desired quality.

Next, pay attention to the grading specifications. Different grades can yield varying results in your applications. Sometimes, a lower-grade powder might suffice for less critical uses. However, you should not overlook the possibility of poor performance due to inadequate grading. Always evaluate the end application carefully.

In the end, practicality can lead to imperfections. Some may struggle with the technical aspects of grading equipment. This can lead to frustrations and potential errors. Regularly revisiting your grading process can help identify areas for improvement. Emphasizing quality is essential to avoid underwhelming results.

Alloy Powder Grader Tips for Perfect Material Quality

Common Challenges in Alloy Powder Grading and Solutions

Grading alloy powders is not straightforward. Many factors can affect the quality of the material. Variations in particle size can lead to inconsistencies. For instance, if too many fine particles are present, they can cause clumping. This interferes with the flow and properties of the final product.

Another challenge is the uniformity of the alloy composition. An inconsistent mix can result in defects. For example, a lack of homogeneity might pose risks during production. Regular testing and characterization of the powder are essential to ensure a balanced composition. However, testing methods can sometimes yield unreliable results, leading to further complications.

Additionally, the environmental conditions during grading can affect outcomes. Humidity and temperature should be monitored closely. Ignoring these variables can lead to moisture absorption, which alters powder behavior. Continuous improvement is key. Reflecting on these challenges helps refine the grading process.

Alloy Powder Grader Tips for Perfect Material Quality

| Challenge | Common Issues | Solutions |

|---|---|---|

| Particle Size Distribution | Inconsistent powder flow and packing density. | Use of standardized sieving and laser diffraction methods for accurate measuring. |

| Contamination | Presence of foreign particles affecting the quality. | Implement clean-room environments and thorough material handling protocols. |

| Moisture Content | Decreased powder performance and compromised mechanical properties. | Utilize desiccation and humidity-controlled storage solutions. |

| Bulk Density Inconsistency | Variations in powder behavior during processing. | Regular calibration of grading equipment and process optimization. |

| Poor Flowability | Clumping or bottlenecks in powder handling. | Additives or surface treatments to enhance flow mechanisms. |

Best Practices for Maintaining Optimal Grader Performance

Maintaining optimal grader performance is crucial for ensuring material quality in alloy powder grading. Regular inspections and maintenance procedures can vastly increase efficiency. For instance, factors like particle size distribution and moisture content impact the final product's quality. Reports indicate that 30% of grading inconsistencies stem from poor equipment upkeep.

Tip: Regularly calibrate your grading machines. This simple practice can help address any calibration drifts and ensure accurate particle measurements. A study found that machines calibrated every month performed 15% better than those calibrated quarterly.

Operators often overlook wear and tear on grading screens. This negligence can lead to increased downtime and product waste. A leading industry analysis highlights that 25% of production delays are related to unmaintained screens.

Tip: Inspect screens for tears or blockages. Scheduling frequent checks can prevent costly breakdowns and enhance throughput. Proper training for operators can also make a significant difference. An informed team can spot issues early, saving time and resources.