2026 Best Ball Bearing Types for Enhanced Performance?

In the realm of engineering, the importance of high-quality Ball Bearings cannot be overstated. Experts like Dr. Emily Carter, a leading figure in tribology, state, "Choosing the right ball bearing can make or break equipment performance." Her insight highlights the critical role that ball bearings play in machinery efficiency.

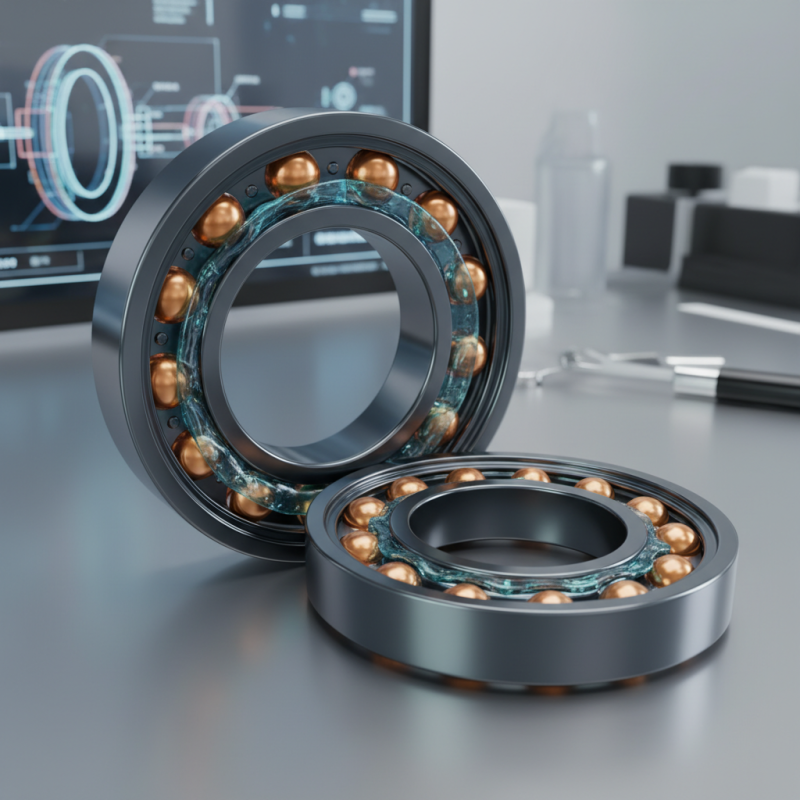

Ball bearings reduce friction and ensure smooth rotation. This key component is found in countless applications. From electric motors to bicycles, their impact is vast. However, not all ball bearings are created equal. Variability in materials and designs leads to differing performance outcomes.

The year 2026 will unveil new innovations in ball bearing technology. Designers and engineers are constantly searching for enhancements. Yet, there remains a need for reflection on past mistakes. Understanding previous failures can foster better choices today. Ultimately, the right ball bearing can elevate performance significantly.

Types of Ball Bearings: An Overview of Options Available

When choosing ball bearings, understanding their types is crucial. There are several options available, each with unique benefits. Deep groove ball bearings are common. They support both radial and axial loads. Their versatility makes them widely used in various applications. However, they can wear out quickly under heavy loads.

Additionally, angular contact ball bearings offer an edge. They handle high-speed operations effectively. These bearings excel in applications requiring precise alignment. Still, their installation can be tricky. Misalignment could lead to premature failure and excessive friction.

Next, we have thrust ball bearings. Designed specifically for axial loads, these are perfect for car wheels and heavy machinery. Yet, they have limitations. They don't manage radial loads well. Proper use is essential for optimal performance. In the world of ball bearings, understanding the types is just the beginning. Each has its strengths and weaknesses, challenging users to choose wisely.

2026 Best Ball Bearing Types for Enhanced Performance

| Bearing Type | Material | Load Capacity (kg) | Speed Rating (rpm) | Temperature Range (°C) |

|---|---|---|---|---|

| Deep Groove Ball Bearing | Steel | 400 | 3000 | -20 to 120 |

| Angular Contact Ball Bearing | Ceramic | 350 | 2500 | -40 to 150 |

| Self-Aligning Ball Bearing | Stainless Steel | 500 | 2000 | -20 to 120 |

| Thrust Ball Bearing | Bronze | 600 | 1500 | -10 to 110 |

| Ball Bearing for High Speed | Carbon Steel | 300 | 4000 | -20 to 90 |

Key Features and Benefits of Different Ball Bearing Types

Ball bearings are essential in various applications, and choosing the right type can significantly enhance performance. Different ball bearing types offer unique features. For instance, deep groove ball bearings are known for their versatility and ability to handle both radial and axial loads. According to a 2022 industry report, they are the most widely used bearing type in applications ranging from electric motors to automotive components.

Another popular option is angular contact ball bearings. These bearings are designed for high-speed applications. They handle higher axial loads while allowing for precise alignment. A study from 2023 indicates that angular contact bearings can improve system efficiency by up to 30% compared to standard types. However, they require careful installation; misalignment can lead to premature failure.

Finally, there are thrust ball bearings. They excel in applications requiring minimal axial movement. They provide reliability in machinery but might not perform well under heavy radial loads. The 2022 study highlighted that using thrust ball bearings in unsuitable contexts can lead to increased vibration and reduced lifespan. Thus, understanding the specific requirements of your application is crucial for selecting the best ball bearing type.

Applications of Ball Bearings in Various Industries

Ball bearings play a crucial role in many industries. They reduce friction between moving parts, allowing for smoother operations. In automotive applications, they are used in wheels and engines. This helps improve vehicle performance and fuel efficiency. In the aerospace sector, ball bearings support high-speed and high-load operations. Their reliability is vital for safety in flights.

As for manufacturing, ball bearings are key in conveyor systems. They enable continuous motion, minimizing downtime. However, not all bearings perform optimally under certain conditions. Overheating can lead to failure. Regular maintenance and inspection are often overlooked but are necessary. In some cases, choosing the wrong type can result in costly repairs and production delays.

Looking at the medical field, ball bearings assist in surgical instruments and equipment. They ensure precision and reliability. Yet, the challenge remains in ensuring they meet strict cleanliness standards. A minor oversight can lead to significant consequences. These real-world applications illustrate the importance of understanding the specific requirements of each industry.

Factors Influencing the Performance of Ball Bearings

Ball bearings play a crucial role in machinery's efficiency and longevity. Various factors influence their performance, including material, design, and lubrication. The choice of bearing material affects strength and wear resistance. Stainless steel is common but not always the best option. Plastic bearings can excel in specific environments, offering lightweight advantages.

Design aspects, such as ball size and cage type, also matter. Larger balls may distribute loads better but could complicate fitting. The design must align with specific usage scenarios. Lubrication is another point often overlooked. Insufficient or inappropriate lubrication may lead to overheating and early failure. Regular maintenance is essential, yet it can be neglected in busy settings.

Temperature affects performance too. High heat can degrade lubricants and materials. Cold environments may cause stiffness. Understanding these factors is vital for optimal performance. Continuous learning from operational challenges helps refine choices, illustrating the necessity of adaptability in bearing selection.

Future Trends in Ball Bearing Technology for Enhanced Efficiency

The future of ball bearing technology is focused on enhancing efficiency and performance. Innovations in materials are paving the way for lightweight solutions that can withstand high loads. Advanced ceramics are becoming popular due to their resistance to wear and corrosion. This could lead to longer lifespans and less frequent replacements.

Another trend is the development of smart bearings. These bearings incorporate sensors to monitor conditions in real-time. They provide valuable data, allowing for predictive maintenance. However, integrating technology with traditional mechanics presents challenges. Issues such as data security and compatibility must be addressed.

In addition, lubrication systems are evolving. New self-lubricating materials reduce friction without constant maintenance. This can save time and costs for industries relying on reliability. Yet, the effectiveness of such systems in extreme conditions remains a point of reflection. Balancing innovation with practical application is crucial for the future of ball bearings.