10 Ways Best Laser Part Marking Improves Productivity by 30 Percent

As industries continue to evolve in the face of increasing demands for efficiency and precision, Laser Part Marking has emerged as a pivotal technology that significantly enhances productivity. According to a report by MarketsandMarkets, the laser marking market is projected to reach USD 5.6 billion by 2025, growing at a CAGR of 5.5%. This growth underscores the critical role of laser marking solutions across various sectors including aerospace, automotive, and electronics. Moreover, a study published in the Journal of Manufacturing Processes indicates that implementing Laser Part Marking can boost operational productivity by as much as 30%. Such improvements are attributed to the technology's ability to provide permanent, high-quality markings that integrate seamlessly into automated production lines, thereby reducing downtime and streamlining workflows. As we delve into the ten ways that Laser Part Marking contributes to enhanced productivity, it becomes evident that companies leveraging this advanced technology can achieve a substantial competitive edge in today's fast-paced market.

Enhancing Workflow Efficiency: The Role of Laser Part Marking in Manufacturing

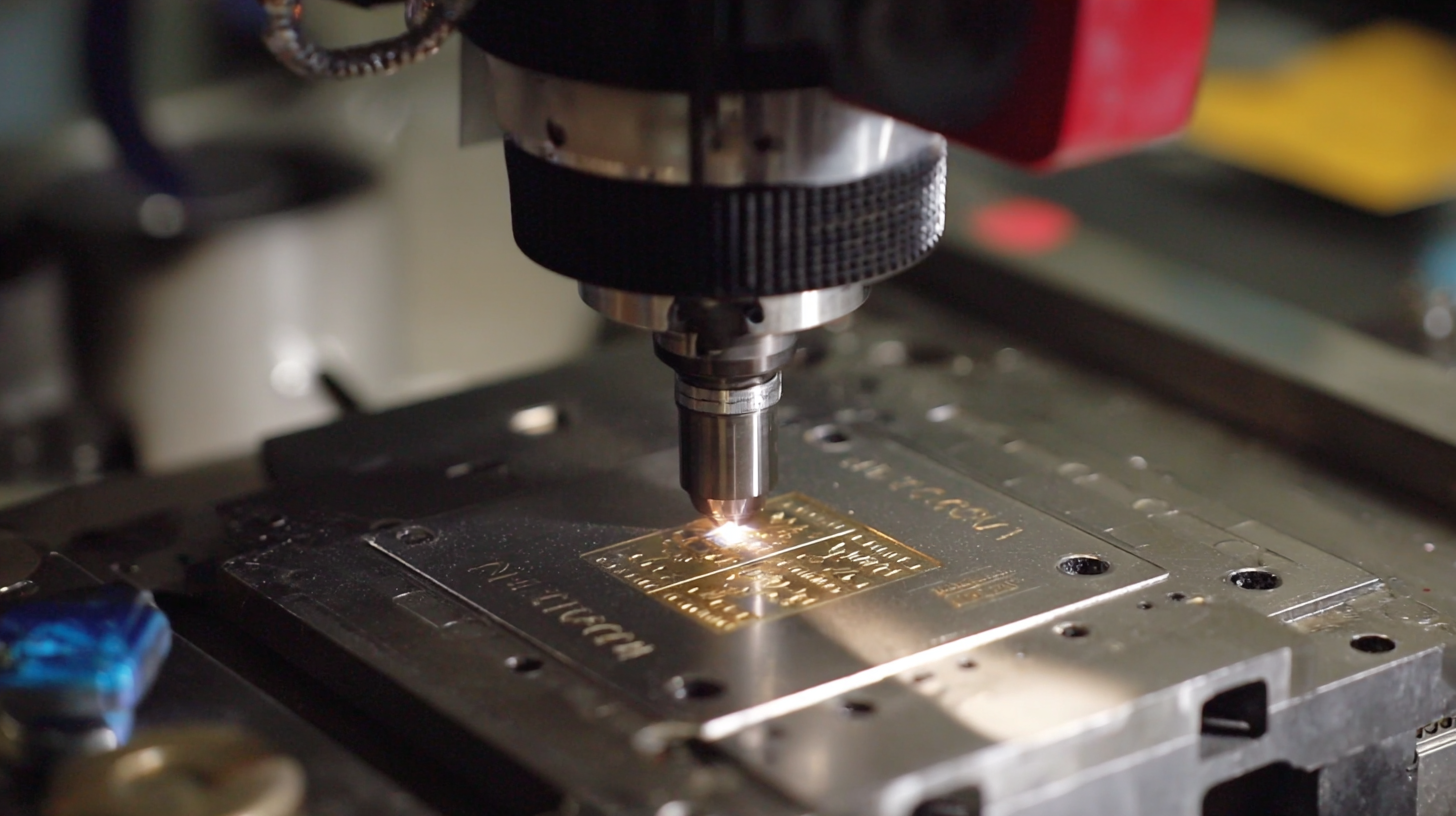

In today’s fast-paced manufacturing landscape, enhancing workflow efficiency is paramount. One technology that has gained significant traction is laser part marking. Unlike traditional marking methods, laser marking provides precision and speed, which are crucial for maintaining high productivity levels. Implementing laser part marking not only streamlines the marking process but also reduces the risk of errors, leading to more consistent product quality. As teams experience fewer disruptions and are able to focus on their core tasks, overall productivity sees a substantial increase.

Moreover, the adaptability of laser marking systems allows for seamless integration into existing manufacturing processes. This flexibility means that manufacturers can quickly adjust markings for various products without needing extensive retooling, thus minimizing downtime. By eliminating the need for physical inks or labels, laser marking significantly cuts operational costs and reduces waste. As manufacturers prioritize efficiency and sustainability, adopting laser marking technology can be a game-changer, propelling productivity gains of up to 30 percent and positioning businesses to better meet market demands.

10 Ways Best Laser Part Marking Improves Productivity by 30 Percent

| Method | Impact on Productivity (%) | Workflow Efficiency Improvement | Reduction in Errors (%) |

|---|---|---|---|

| High-Speed Marking | 30% | Increased throughput | 10% |

| Minimal Setup Time | 25% | Faster job changes | 5% |

| Non-Contact Marking | 28% | Preserved part integrity | 3% |

| Versatility | 30% | Adaptable to different materials | 7% |

| Traceability and Compliance | 35% | Improved accountability | 2% |

Reducing Downtime: How Laser Marking Streamlines Production Processes

Laser marking technology has revolutionized production processes by significantly reducing downtime. Traditional marking methods often involve lengthy setups, manual adjustments, and frequent maintenance, all of which can disrupt the flow of production. In contrast, laser marking systems are designed for rapid deployment and minimal interruption. Once programmed, these systems can operate continuously, allowing for quick changes in design, text, or barcodes without halting the entire production line.

Furthermore, laser marking enhances precision and consistency, ensuring that every product is marked accurately the first time. This reliability minimizes the need for rework or corrections, further streamlining operations. With the ability to mark materials at high speeds, manufacturers can keep up with increased demands while maintaining quality. As a result, businesses experience a seamless integration of the marking process into their production workflow, ultimately leading to a marked improvement in productivity as processes become more efficient and less prone to delays.

Precision and Accuracy: The Impact of Laser Marking on Quality Control Metrics

The use of laser marking technology is revolutionizing quality control metrics across various industries. With the global laser processing market expected to grow from USD 7.17 billion in 2025 to USD 11.89 billion by 2032, achieving a CAGR of 8.5%, organizations are increasingly recognizing the precision and accuracy that laser marking provides. This technology not only improves the clarity of markings on products but also significantly enhances traceability and compliance with industry standards.

Laser marking's impact on quality control metrics is profound. The accuracy of laser marking ensures that every product is marked consistently, reducing the chances of human error. As a result, companies can achieve tighter tolerances in their operations, leading to diminished waste and rework. This precision directly contributes to a reported productivity improvement of up to 30%, streamlining processes from production to inspection. As businesses continue to adapt to these cutting-edge technologies, those that leverage laser marking will likely see an advantageous position in quality management and operational efficiency.

Cost-Effectiveness: Analyzing ROI from Laser Part Marking Technology

As industries continually seek ways to optimize operations, laser part marking technology has emerged as a game-changer in enhancing efficiency. The cost-effectiveness of this technology lies in its ability to significantly reduce operational expenses while increasing output. Unlike traditional marking methods, laser marking minimizes material wastage and eliminates the need for consumables like inks and solvents, resulting in lower long-term costs. By automating the marking process, companies can streamline production workflows, leading to reduced labor costs and improved turnaround times.

Furthermore, evaluating the return on investment (ROI) from implementing laser part marking reveals substantial financial benefits. Businesses can expect not only an increase in productivity but also improved product quality and traceability. By ensuring precise markings that withstand harsh environments, manufacturers reduce errors and the need for rework, which can be costly. Over time, the savings in both time and resources translate into a compelling ROI, reinforcing the decision to adopt laser part marking as a core component of their production strategy.

Data-Driven Decision Making: Leveraging Market Insights for Optimized Marking Solutions

In today's fast-paced manufacturing environment, data-driven decision-making is crucial for optimizing processes and enhancing productivity. By leveraging market insights, companies can refine their laser part marking solutions to achieve significant efficiency gains. The ability to analyze production data allows businesses to identify bottlenecks, ensure quality control, and tailor marking strategies that align with specific operational goals. This targeted approach not only minimizes waste but also supports the adoption of advanced techniques that improve throughput.

Furthermore, a deep understanding of market trends and customer needs empowers manufacturers to make informed choices about their marking technologies. While traditional methods may suffice, embracing laser marking offers superior speed and precision, directly translating into a 30 percent increase in productivity. Armed with data, companies can continuously evaluate their operations and adapt to changing demands, ensuring they remain competitive. With the right insights, organizations can not only enhance their marking solutions but also drive overall business growth in a dynamic marketplace.