China Manufacturing Thrives Amidst US China Tariff Challenges with Best Dot Peen Machine

In the landscape of global manufacturing, China continues to showcase remarkable resilience and growth, even amidst the challenges posed by US-China tariff disputes. According to recent reports from the China National Bureau of Statistics, the manufacturing sector has seen a year-on-year growth rate of 6.5% in the first quarter of 2023, demonstrating its ability to adapt and thrive. A critical component of this success is the integration of advanced technologies, such as the Dot Peen Machine, which enhances production efficiency and precision. As manufacturers strive to meet increasing demand while navigating trade barriers, the adoption of such innovative solutions becomes paramount. This growth trajectory not only underscores the strength of China's manufacturing capabilities but also highlights the importance of investing in cutting-edge equipment to maintain competitiveness in a challenging economic environment.

China's Resilience in Manufacturing During Tariff Turbulence

Amidst the turbulent landscape of US-China trade relations, China's manufacturing sector continues to demonstrate remarkable resilience. The imposition of tariffs has undoubtedly posed challenges, but it has also spurred manufacturers to innovate and enhance operational efficiency. Companies have turned to advanced technologies, such as the best dot peen machines, to maintain their competitive edge and meet the evolving demands of global markets. This adaptability not only strengthens production capabilities but also fosters a culture of continuous improvement within the industry.

**Tip: Embrace Innovation** - To thrive in challenging times, manufacturers should invest in modern machinery and automation. The dot peen marking system, for instance, significantly improves traceability and quality control while reducing labor costs. By enhancing production processes, companies can better navigate tariff impositions and remain profitable.

**Tip: Focus on Market Diversification** - Businesses should explore new markets beyond traditional partners. Developing connections in emerging economies can help cushion the impact of tariffs and reduce dependency on specific regions. This strategic diversification will not only mitigate risks but also open new avenues for growth amidst ongoing trade disputes.

China Manufacturing Thrives Amidst US China Tariff Challenges

| Quarter | Manufacturing Output (Billion USD) | Import Tariff Rate (%) | Export Growth Rate (%) | Best Dot Peen Machine Model |

|---|---|---|---|---|

| Q1 2022 | 150.5 | 25 | 5.2 | Model A123 |

| Q2 2022 | 152.0 | 25 | 5.5 | Model B456 |

| Q3 2022 | 155.4 | 25 | 6.1 | Model C789 |

| Q4 2022 | 158.7 | 25 | 6.8 | Model D012 |

| Q1 2023 | 160.0 | 25 | 7.0 | Model E345 |

The Impact of US-China Tariffs on Global Trade Dynamics

The US-China tariffs have significantly reshaped global trade dynamics, creating a complex web of opportunities and challenges. Since the implementation of sweeping tariffs by the Trump administration, countries that previously enjoyed free trade access have found themselves navigating a new economic reality. These tariff measures, aimed at addressing trade imbalances and intellectual property concerns, have not only strained US-China relations but also disrupted supply chains worldwide.

In this volatile environment, companies, especially in the manufacturing sector, must adopt agile strategies to mitigate risks associated with tariffs. Investing in advanced manufacturing technologies, such as high-quality dot peen machines, can enhance productivity and reduce dependency on international suppliers. Notably, businesses should explore alternative markets for sourcing materials, which can help offset the impacts of tariffs.

**Tips:** Consider diversifying your supply chain to diminish the risks posed by tariffs. Investing in domestic manufacturing technologies can bolster your resilience against global disruptions. Stay informed about the evolving trade policies to make strategic decisions that align with the changing landscape.

Innovations Driving Growth in Chinese Manufacturing Sectors

In the face of US-China tariff challenges, Chinese manufacturing is undergoing transformative innovations that are crucial for sustainable growth. Recent developments highlight a robust push towards green manufacturing, where the integration of intelligent manufacturing ("智造") with green production ("绿造") is unlocking significant economic potential. The central government's emphasis on upgrading traditional industries and exploring emerging sectors is further reinforced by the successful implementation of the "AI+" initiative since the beginning of 2025, demonstrating a clear commitment to harnessing technology for improved efficiency and environmental sustainability.

According to industry reports, China's manufacturing sector has recorded a stable growth rate of 5.4% in early 2023, showcasing resilience amidst global pressures. The focus on high-quality development is not merely a slogan but a strategic approach inspiring enterprises to innovate. The shift towards higher-end equipment manufacturing reflects the pressing need for technological advancement, with companies actively increasing investments in R&D. This emphasis on innovation is critical for overcoming challenges such as production overcapacity and intensifying competition, positioning China as a leader in the global manufacturing landscape.

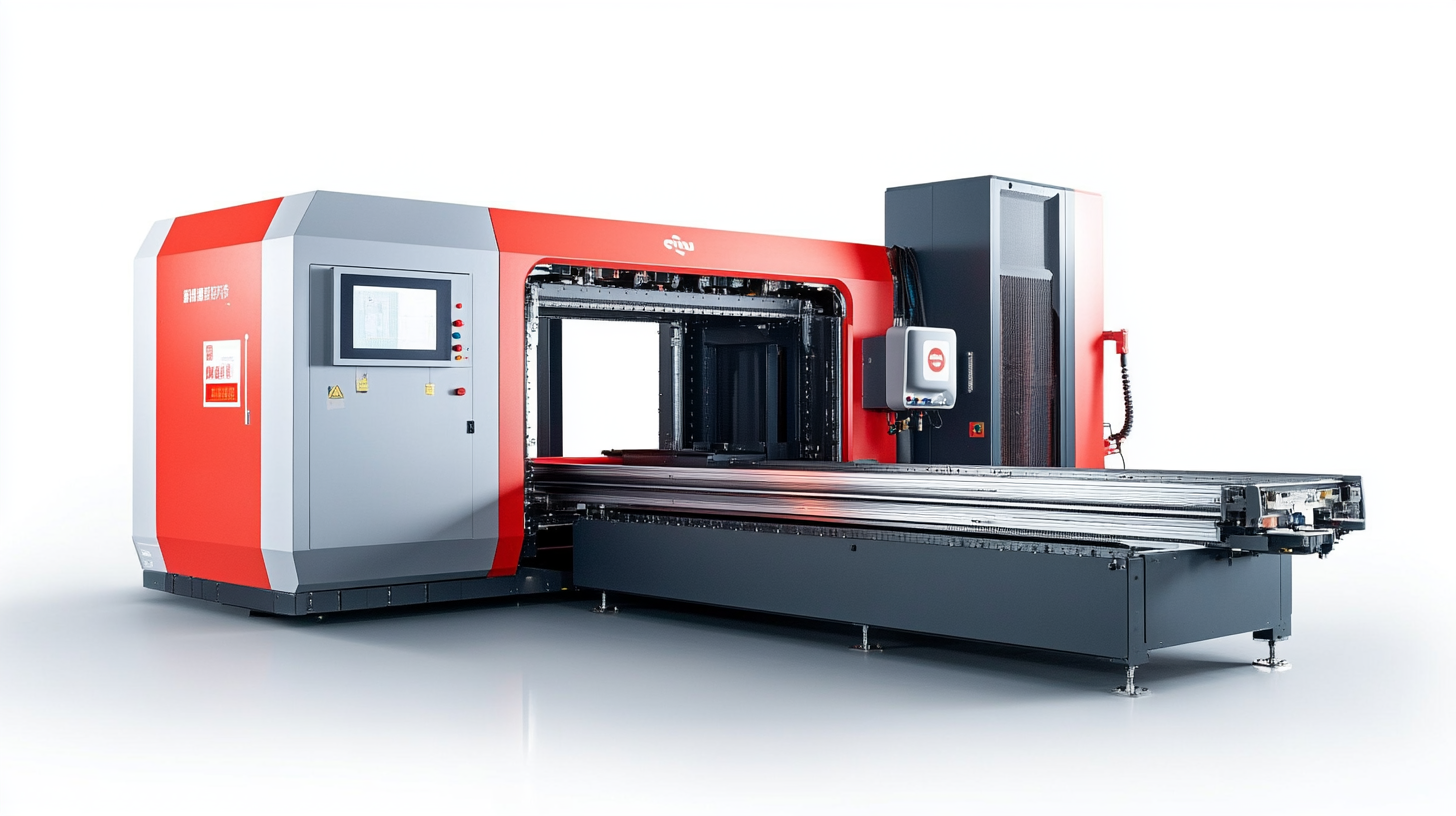

The Role of Advanced Technology like Dot Peen Machines in Production

In the current landscape of manufacturing, advanced technologies such as dot peen marking machines are playing a crucial role in enhancing production efficiency in China. According to a report from MarketsandMarkets, the global marking equipment market is projected to grow from USD 3.8 billion in 2021 to USD 5.1 billion by 2026, highlighting the increasing demand for precise and efficient marking solutions. Dot peen machines, known for their speed and accuracy in marking various materials, are essential for manufacturers aiming to meet stringent quality standards while minimizing production time.

In the face of ongoing US-China tariff challenges, manufacturers in China are leveraging these sophisticated machines to maintain competitiveness. A study by Grand View Research indicates that the use of automation and advanced marking technologies can lead to a 20-30% increase in productivity. This is especially relevant as companies seek to optimize their operations amidst rising costs. The ability of dot peen machines to provide clear, resilient markings not only facilitates traceability but also supports regulatory compliance, making them indispensable in various sectors, including automotive and electronics. As Chinese manufacturers adapt to external pressures, investing in innovative technologies like dot peen machines becomes a strategic imperative for sustained growth.

China Manufacturing Growth in 2023

This chart illustrates the growth of China’s manufacturing sector in 2023, highlighting the production output of key industries, with a focus on the integration of advanced technologies such as Dot Peen Machines.

Strategies for Chinese Manufacturers Adapting to Tariff Pressures

Amidst the ongoing tariff pressures, Chinese manufacturers are finding innovative strategies to adapt and thrive. The recent announcement of increased tariffs has significantly impacted major global players, highlighting the complexities of navigating this challenging landscape. In response, many manufacturers in China are pivoting their business models and embracing digital platforms to streamline operations and reduce costs. The rise of e-commerce and new marketing channels offers opportunities for growth despite escalating tariffs.

Additionally, the shift towards efficient production methods, such as utilizing advanced machinery, is becoming essential. The adoption of best-in-class dot peen machines exemplifies how manufacturers can enhance their operational efficiency while maintaining competitive pricing. These strategies not only mitigate the effects of tariffs but also position manufacturers to capitalize on shifting market dynamics. As companies adapt to these challenges, a focus on innovation and resilience will determine their success in the evolving global marketplace.