Unleashing the Power of China's Manufacturing Excellence with the Best Dot Peen Marking Machine

In today's fiercely competitive global market, China has emerged as a pivotal player in the manufacturing sector, showcasing remarkable advancements in technology and efficiency. One vital component in this landscape is the Dot Peen Marking Machine, a tool that enhances traceability, information management, and branding on a wide range of materials. According to a recent market analysis, the demand for advanced marking technology is projected to grow by over 5% annually, driven by increased automation in manufacturing processes. The Dot Peen Marking Machine stands out for its precision and speed, making it indispensable for industries that require high-quality marking solutions, such as automotive, aerospace, and electronics. As manufacturers leverage the capabilities of such technology, they not only improve their operational outcomes but also contribute to the broader Chinese manufacturing excellence narrative, positioning themselves for success in a digitized economy.

Exploring the Versatility of Dot Peen Marking Machines in Diverse Industries

In today's competitive landscape, dot peen marking machines have become invaluable tools across a variety of industries. Their versatility lies in their ability to produce durable, clear, and precise markings on an array of materials, such as metals, plastics, and composites. This makes them ideal for applications ranging from automotive to aerospace, where identification and traceability are crucial. The ability to customize texts, logos, and barcodes seamlessly enhances brand identity while ensuring compliance with industry standards.

Moreover, the robustness of dot peen marking technology allows manufacturers to adapt to different production environments. Whether in a factory setting or on-site, these machines can operate efficiently without sacrificing quality. The integration of such technology into manufacturing processes not only increases productivity but also reduces operational costs. As businesses continue to embrace advanced marking solutions, the significance of dot peen marking machines will only grow, driving innovation and excellence in manufacturing practices worldwide.

Key Features of Different Types of Dot Peen Marking Machines

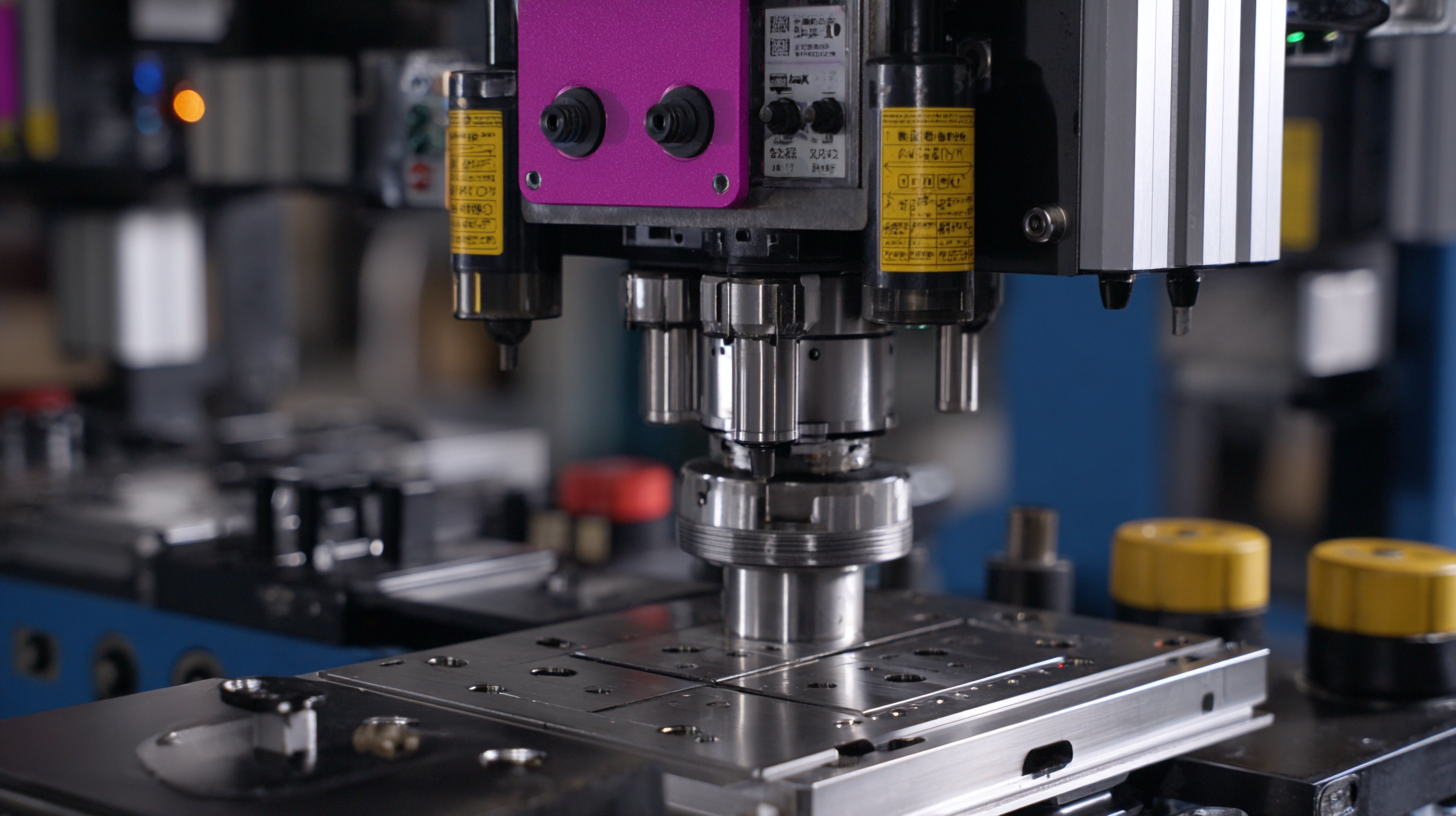

Dot peen marking machines are essential tools in modern manufacturing, offering precise and durable marking solutions for various materials. The key features of different types of dot peen marking machines can significantly impact productivity and engraving quality. For instance, portable dot peen markers provide flexibility for on-site applications, making them ideal for industries requiring quick setup and mobility. Their lightweight design coupled with battery operation allows operators to mark parts directly on the production floor without needing to transport components to a fixed station.

On the other hand, stationary dot peen marking systems excel in heavy-duty tasks, often featuring advanced automation capabilities. These machines can handle larger workpieces and are designed for high-volume production environments. Key features such as programmable software and adjustable marking speeds enable manufacturers to tailor specifications to their unique needs, ensuring consistent quality across large batch productions. Additionally, some advanced models include integrated vision systems for enhanced accuracy and reliability in marking data, such as barcodes or serial numbers. Investing in the right type of dot peen marking machine is crucial to unlocking the full potential of China’s manufacturing excellence.

Applications of Dot Peen Marking in Manufacturing: A Comprehensive Overview

Dot peen marking technology has become an integral part of modern manufacturing processes, enabling precise and durable marking on a variety of materials. This versatile technique is widely used in industries ranging from automotive to aerospace, allowing for the identification of parts, tracking of inventory, and even conducting quality control checks. The ability to create high-contrast marks on metals, plastics, and even ceramics makes dot peen marking machines invaluable for manufacturers aiming to enhance traceability and compliance.

When implementing dot peen marking in your operations, consider the following tips to maximize efficiency and accuracy. First, ensure that the machine is compatible with the materials you are working with, as different substrates require specific marking settings. Additionally, regular maintenance of the marking machine can prevent downtime and ensure consistent quality in your marks. Lastly, training your operators on best practices can enhance their understanding of the machine’s capabilities, leading to better results and productivity.

With the rise of industrial automation, dot peen marking is also evolving. Advanced machines now incorporate digital connectivity features that allow manufacturers to integrate marking processes with their ERP systems. This facilitates real-time data usage for better inventory management and product tracking, ensuring that businesses can maintain their competitive edge in today’s fast-paced manufacturing environment.

Choosing the Right Dot Peen Marking Machine for Your Production Needs

When selecting a dot peen marking machine for your production needs, it's crucial to consider several key factors that align with your operational requirements. A comprehensive report from Market Research Future indicates that the global dot peen marking machine market is projected to grow at a CAGR of 4.5% from 2020 to 2025. This growth underscores the increasing importance of precision and efficiency in manufacturing, making the right choice of marking equipment even more pivotal.

One of the primary considerations should be the machine's adaptability to different materials. Various industries, from automotive to electronics, require robust marking solutions that can handle metals, plastics, and composites. According to a study by Technavio, 35% of manufacturers cited versatility as a critical factor in their purchasing decisions. Additionally, evaluating the machine's speed and production capacity is essential; with the demand for efficient production processes rising, units that can deliver high volumes without sacrificing quality will be in greater demand. Understanding these dynamics will enable manufacturers to choose a dot peen marking machine that not only meets but exceeds their production objectives.

Manufacturing Output Comparison of Various Industries in China (2022)

Best Practices for Operating Dot Peen Marking Machines Effectively

In the dynamic landscape of modern manufacturing, the effective operation of dot peen marking machines is crucial for maintaining efficiency and product quality. Research from the Freedonia Group indicates that the global demand for marking machinery is expected to reach $4.2 billion by 2025, with a significant portion attributed to the precision offered by dot peen technology. This technology enables manufacturers to create durable marks on a variety of materials, ensuring traceability and compliance with industry standards.

To maximize the benefits of dot peen marking machines, operators should implement best practices that enhance performance. Proper training and technique are vital; studies have shown that well-trained operators can improve marking speed by up to 30%, reducing bottlenecks in production. Additionally, regular maintenance of the machines, including checking the marking pins and ensuring proper alignment, can decrease the downtime caused by equipment failure.

Furthermore, operators should embrace the integration of software solutions that optimize machine settings according to material type and marking requirements. The ability to tailor marking parameters not only improves the quality of the final product but also minimizes wear and tear on the machinery, extending its lifespan. As highlighted by a report from Technavio, companies that leverage advanced automation and software capabilities can enhance their operational efficiency by up to 25%.

Unleashing the Power of China's Manufacturing Excellence with the Best Dot Peen Marking Machine - Best Practices for Operating Dot Peen Marking Machines Effectively

| Aspect | Best Practices | Benefits |

|---|---|---|

| Machine Maintenance | Regular cleaning and lubrication | Increases longevity and performance |

| Operator Training | Comprehensive training programs | Reduces errors and improves efficiency |

| Workpiece Preparation | Ensure clean and flat surfaces | Enhances marking quality |

| Marking Parameters | Optimize speed and pressure settings | Improves clarity and depth of marks |

| Software Utilization | Use the latest software for design | Enhances customization and ease of use |

| Safety Protocol | Implement and follow safety measures | Prevents accidents and ensures compliance |