How to Choose the Right Fiber Laser Enclosure for Your Business Needs

In the rapidly evolving landscape of manufacturing and fabrication, the selection of the appropriate Fiber Laser Enclosure is crucial for optimizing performance and ensuring safety. According to a report by MarketsandMarkets, the global fiber laser market is projected to reach USD 3.25 billion by 2026, highlighting the growing reliance on fiber laser technology for cutting, welding, and marking applications. A well-designed enclosure not only enhances operational efficiency but also protects personnel from high-intensity laser beams, which can be hazardous without proper safeguards. Furthermore, the enclosure must accommodate the specific size and power needs of the fiber laser systems while ensuring compliance with industry safety standards. As businesses strive to remain competitive in a technology-driven environment, understanding the nuances of choosing the right Fiber Laser Enclosure can significantly impact productivity and workplace safety.

Understanding the Importance of Fiber Laser Enclosures for Safety and Productivity

Fiber laser enclosures play a crucial role in ensuring safety and productivity within the work environment. According to a report by the Laser Institute of America, 31% of workplace accidents involving laser equipment can be attributed to inadequate safety measures, emphasizing the need for effective laser enclosures. These enclosures not only protect operators from hazardous laser emissions but also minimize the risk of fire hazards, which can be detrimental in a manufacturing setting. A study by the Occupational Safety and Health Administration (OSHA) found that workplaces with proper safety protocols, including effective laser shielding, experienced a 25% reduction in workplace incidents.

Moreover, investing in a high-quality fiber laser enclosure can enhance productivity. Industry research indicates that properly contained laser systems can improve beam quality and reduce downtime caused by maintenance issues. For example, a report by the American Society of Mechanical Engineers (ASME) notes that businesses that utilize comprehensive laser safety enclosures report up to a 20% increase in operational efficiency. This is largely due to minimized distractions and improved focus among workers who are assured of a safer working environment. By understanding the importance of fiber laser enclosures, businesses can make informed decisions that align with their safety protocols and productivity goals.

Key Specifications to Consider When Selecting a Fiber Laser Enclosure

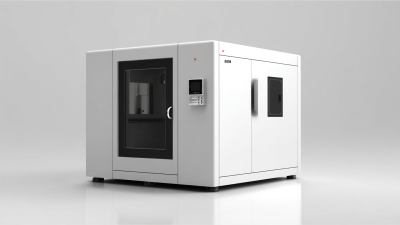

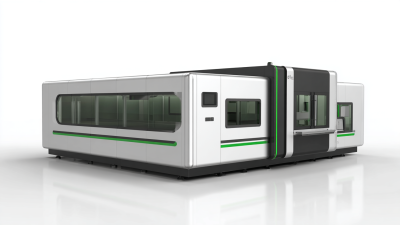

When selecting a fiber laser enclosure for your business needs, it's crucial to consider specific key specifications that can significantly impact both safety and efficiency. First, assess the size of the enclosure. It should accommodate your laser machine while allowing for adequate workspace. A compact design may save space but ensure that it doesn’t compromise accessibility or ventilation.

Tip: Measure your existing workspace and choose an enclosure that provides extra room for safety and maintenance tasks.

Next, look into the materials used in construction. High-quality enclosures are often made from robust materials that can withstand heat and offer better durability. Additionally, ensure that the enclosure has proper safety features, like interlocks and safety glasses, to protect your operators from potential hazards like laser radiation.

Tip: Always check for certifications that guarantee the enclosure meets industry standards for safety and performance.

Lastly, consider your specific operational needs, such as noise reduction and fume extraction systems. An effective enclosure should minimize noise pollution and adequately ventilate any harmful fumes produced during the laser process, ensuring a safe working environment.

Tip: Evaluate your business's particular operational requirements to choose an enclosure that provides optimal working conditions tailored to your needs.

Evaluating Different Materials and Designs for Laser Enclosures

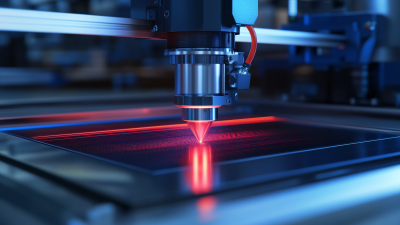

When selecting the right fiber laser enclosure, evaluating the materials and designs is crucial for ensuring safety and efficiency in your business operations. Various materials can impact the durability and functionality of the enclosure. For instance, enclosures made from metal materials may provide better structural integrity and heat resistance, which is beneficial when dealing with high-energy laser processes. In contrast, transparent materials can offer visibility for monitoring operations but might require additional safety features to protect users from hazardous light emissions.

Design considerations also play a significant role in the performance of laser enclosures. Proper ventilation and airflow can help mitigate the spattering observed during processes like selective laser melting, where liquid metal particles can escape and potentially damage surroundings. Innovative designs that optimize space and enhance accessibility for maintenance can further improve operational efficiency. As the industry evolves, reviewing the latest advancements in enclosure technology will ensure that businesses can select optimal solutions tailored to their specific requirements while maintaining a safe work environment.

Material Comparison for Fiber Laser Enclosures

Cost-Benefit Analysis of Investing in High-Quality Fiber Laser Enclosures

When considering the purchase of a fiber laser enclosure, conducting a thorough cost-benefit analysis is essential to maximize your investment. High-quality enclosures often come with a higher upfront cost, but they can significantly enhance operational efficiency and safety. For instance, premium enclosures that provide adequate shielding from hazardous laser emissions minimize the risk of workplace accidents, potentially saving businesses from costly insurance claims and downtime due to safety violations. Furthermore, well-designed enclosures help in controlling the work environment by reducing dust and fumes, leading to better overall product quality and fewer defects.

In the long run, investing in a high-quality fiber laser enclosure can lead to substantial savings. Durable materials and superior craftsmanship reduce the need for frequent repairs and replacements, thereby lowering maintenance costs. Additionally, enhanced energy efficiency features may lead to reduced utility bills. By weighing these long-term benefits against the initial investment, businesses can better understand the overall value of choosing a reliable and effective fiber laser enclosure, ensuring that their operational needs are met while also safeguarding their financial future.

Regulatory Standards and Compliance for Fiber Laser Enclosure Safety

When selecting a fiber laser enclosure, adhering to regulatory standards and compliance requirements is of paramount importance. Organizations like the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) have set forth stringent guidelines to ensure worker safety and prevent hazardous exposures to laser emissions. For example, ANSI Z136.1-2014 outlines specific requirements for laser safety, mandating enclosures that limit accessible emissions to a Non-Hazardous Class. This demonstrates a clear commitment to professional safety in environments utilizing high-powered laser systems.

Moreover, compliance with these standards can also significantly impact operational efficiency. According to a report by MarketsandMarkets, the global laser safety equipment market is projected to reach $579 million by 2025, driven by increasing regulations on laser use. Proper fiber laser enclosures not only fulfill compliance obligations but also contribute to the longevity and reliability of equipment. Furthermore, investing in enclosures that meet industry regulations can help mitigate risks associated with non-compliance, reducing liabilities and enhancing the overall safety culture within the organization.

Related Posts

-

7 Essential Tips for Choosing the Best Fiber Laser Enclosure for Your Business Needs

-

Ultimate Guide to Choosing the Best Fiber Laser Enclosure for Optimal Safety and Efficiency

-

Choosing the Right Manufacturer for the Best Fiber Laser Marking Machine to Meet Your Global Needs

-

5 Key Advantages of Using Laser Part Marking Machines for Global Procurement

-

How to Navigate the Global Marking Machine Market Trends for 2025 with Key Industry Insights

-

Challenges in Selecting the Right Laser Part Marking Machinery