Ultimate Guide to Choosing the Best Fiber Laser Enclosure for Optimal Safety and Efficiency

In the rapidly evolving field of laser technology, the significance of a well-designed Fiber Laser Enclosure cannot be overstated. Recent industry reports indicate that the global fiber laser market is projected to reach $6.6 billion by 2026, growing at a CAGR of 10.5% from 2021 to 2026. With this surge in adoption, ensuring optimal safety and efficiency in laser operations becomes paramount. An effective Fiber Laser Enclosure not only protects operators from harmful radiation but also enhances the overall performance of laser systems by minimizing contamination and environmental interferences. As businesses prioritize compliance with safety standards and seek to improve operational efficiency, understanding the critical components and features of fiber laser enclosures is essential for making informed decisions. In this guide, we will explore the key considerations for selecting the best fiber laser enclosure, ensuring that your investment leads to significant returns in safety and operational excellence.

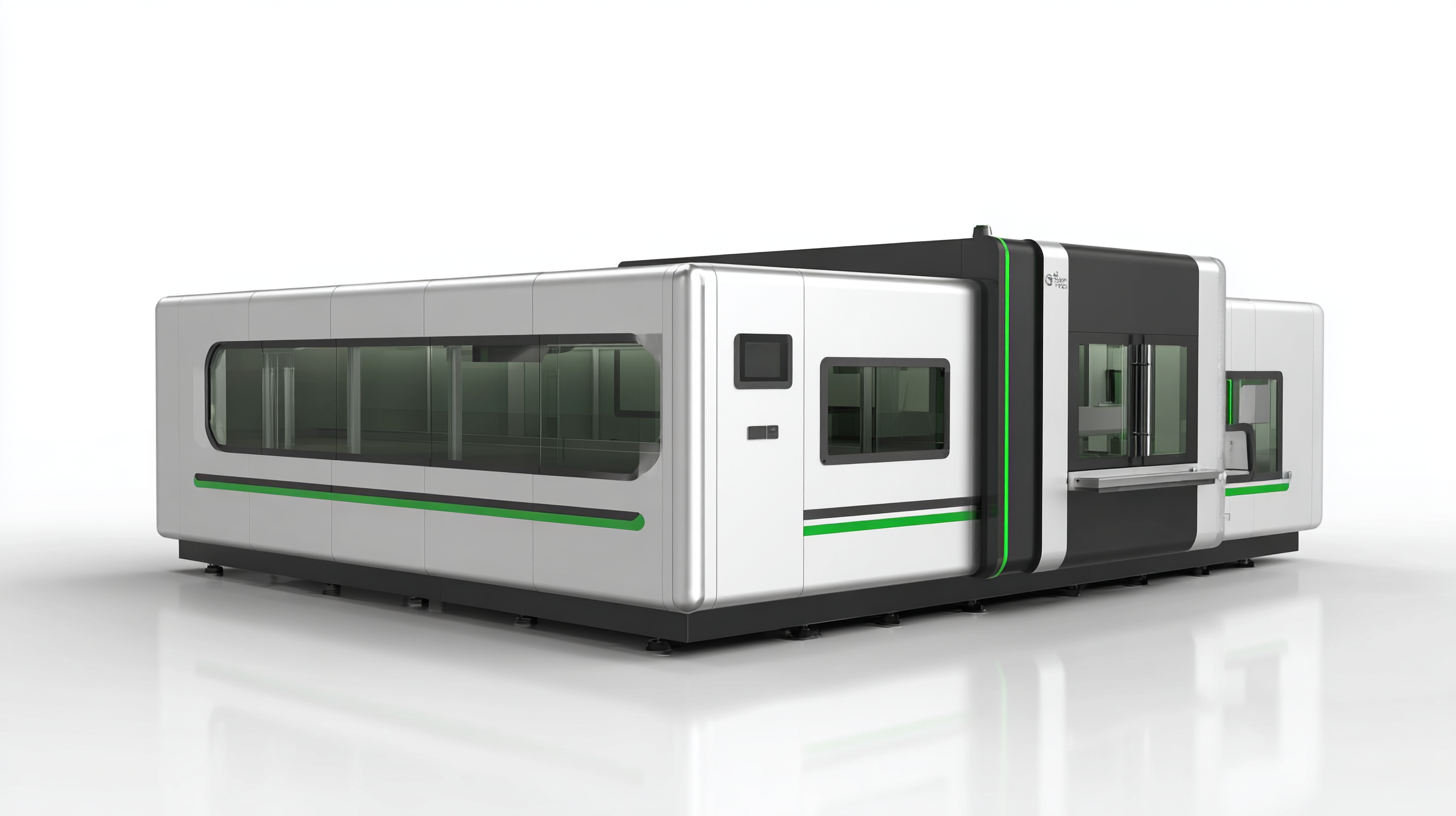

Understanding the Importance of Fiber Laser Enclosures for Safety and Efficiency

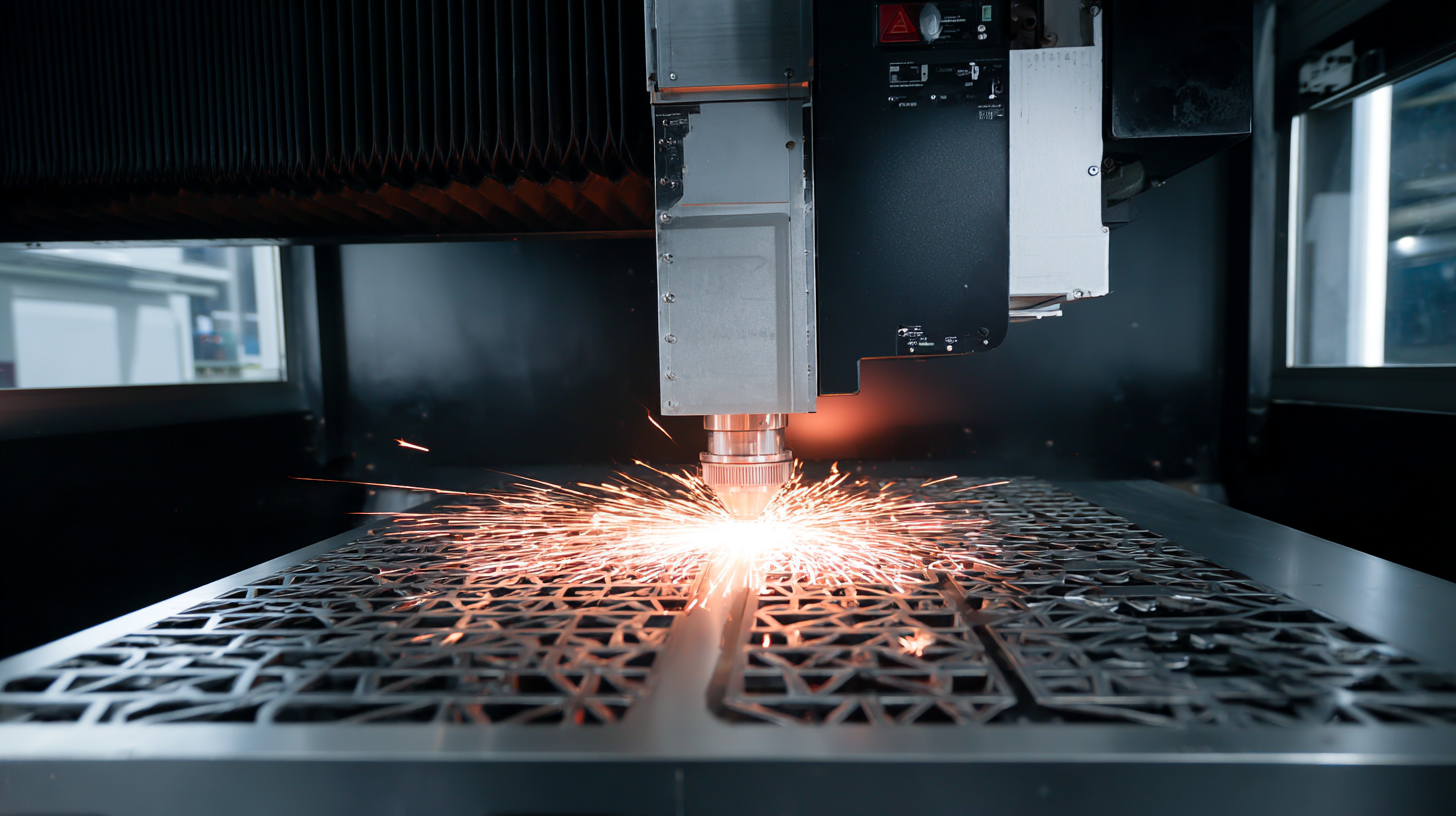

Fiber laser enclosures play a crucial role in enhancing both safety and efficiency in the use of fiber laser systems. These enclosures are designed to contain harmful laser emissions, protecting operators and nearby personnel from exposure. By providing a safe working environment, they reduce the risk of accidents and ensure compliance with safety regulations. Moreover, enclosures can also minimize the risk of damage from debris or contamination during the laser cutting process, leading to higher quality outputs and reduced downtime.

In addition to safety, fiber laser enclosures contribute to operational efficiency. By creating a controlled environment, they help maintain optimal conditions for laser operation, such as temperature and ventilation, which are essential for consistent performance. Enclosures often come equipped with advanced features like filtering systems and automated safety mechanisms, further enhancing their effectiveness. As industries increasingly adopt fiber laser technology, prioritizing adequate enclosures will be key to maximizing both safety and productivity in laser applications.

Key Features to Look for in Fiber Laser Enclosures

When selecting the optimal fiber laser enclosure, safety and efficiency should be top priorities. Key features that enhance these aspects include robust construction materials, proper ventilation systems, and effective noise reduction technology. A well-built enclosure can minimize the risk of laser exposure accidents while providing a stable environment for the equipment, ultimately leading to enhanced performance and longevity. According to industry reports, enclosures constructed with high-grade materials can reduce the risk of fire hazards, a common concern for laser operations, by up to 70%.

Ventilation is another crucial element, as laser cutting and engraving can produce harmful fumes and particulates. Enclosures that include integrated exhaust systems not only improve air quality but also maintain optimal working conditions, enhancing user comfort and operational efficiency. Additionally, features like interlock systems and safety glasses storage enhance the overall safety protocols for users, ensuring compliance with industry standards. Research has shown that implementing these safety measures can boost productivity by over 25% as employees feel more secure in their work environment.

Navigating Industry Standards and Certifications for Laser Enclosures

When selecting a fiber laser enclosure, understanding industry standards and certifications is crucial for ensuring optimal safety and efficiency. Fiber lasers are increasingly popular in manufacturing due to their efficiency and precision. According to a recent report by a leading market research firm, the global fiber laser market is expected to reach $3 billion by 2025, growing at a CAGR of 12.3%. This growth highlights the importance of adhering to safety protocols across the industry.

There are various certifications that laser enclosure manufacturers must comply with to ensure the safety of operators and equipment. Key standards, such as the American National Standards Institute (ANSI) Z136.1 for Safe Use of Lasers, provide guidelines for laser safety. Additionally, protective enclosures should ideally meet ISO 13849 and IEC 60204-1 standards, which focus on the safety and reliability of machinery. By prioritizing these certifications, businesses not only protect their workforce but also enhance production efficiency, as compliant enclosures reduce the risk of accidents and downtime associated with safety violations.

Investing in certified enclosures not only elevates safety standards but also boosts productivity, enabling businesses to take full advantage of the technological advancements in laser applications. As industries evolve and become more laser-dependent, being informed about these critical compliance aspects will position companies for sustained growth and innovation.

Comparative Analysis of Popular Fiber Laser Enclosure Brands

When it comes to selecting a fiber laser enclosure, understanding the differences among popular brands can greatly influence both safety and operational efficiency. Key players in the market, such as Fibertech and LaserSafe, offer enclosures with distinct features tailored to various user needs. Fibertech is known for its customizable designs, allowing users to modify dimensions and ventilation options according to their specific workspace requirements. This flexibility can enhance safety by accommodating any size of laser equipment while ensuring optimal airflow, thus preventing overheating.

In contrast, LaserSafe focuses on robust safety standards, emphasizing high-quality materials and built-in safety mechanisms. Their enclosures often come equipped with advanced filtration systems to remove harmful fumes and particles produced during laser cutting. Additionally, the use of heavy-duty glass provides visibility without compromising safety, making it a favored choice among professionals prioritizing both protection and performance. By comparing the attributes of these leading brands, users can make informed decisions that not only enhance the safety of their operations but also improve overall efficiency in their laser applications.

Ultimate Guide to Choosing the Best Fiber Laser Enclosure for Optimal Safety and Efficiency

| Feature | Option A | Option B | Option C |

|---|---|---|---|

| Size | 1200 x 800 mm | 1500 x 1000 mm | 2000 x 1200 mm |

| Material | Steel | Aluminum | Composite |

| Weight | 200 kg | 180 kg | 250 kg |

| Safety Features | Class 1 Enclosure | Emergency Stop | Ventilation System |

| Price Range | $700 - $900 | $900 - $1200 | $1200 - $1500 |

| Warranty | 2 Years | 1 Year | 3 Years |

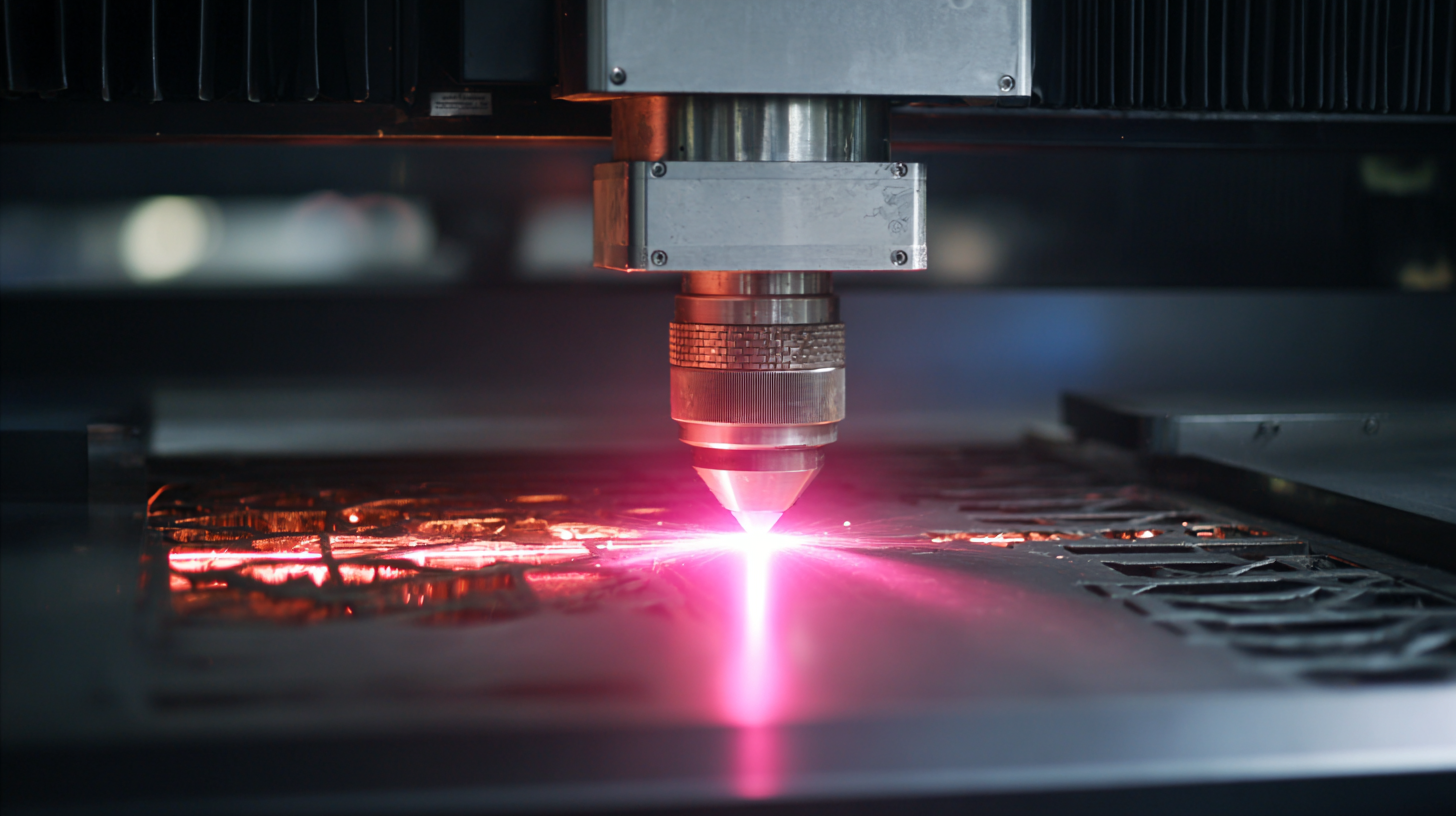

Best Practices for Maintaining and Using Fiber Laser Enclosures Safely

When it comes to fiber laser enclosures, maintaining safety and efficiency requires diligent attention to best practices. First and foremost, regular inspections of the enclosure are crucial. Check for any signs of wear and tear, ensuring that all components remain intact and functional. This includes verifying that safety interlocks are operational, as they play a vital role in preventing accidental exposure to laser radiation. Additionally, keeping the enclosure clean and free of debris will not only maintain visibility but also help prevent any potential fire hazards associated with flammable materials.

Operational protocols are also essential for safe use. Users should be trained thoroughly on how to operate the fiber laser system within the enclosure, emphasizing the importance of personal protective equipment (PPE). Ensure that safety goggles rated for the specific wavelength of the laser are worn by all personnel in the vicinity. Moreover, it’s vital to establish clear communication and emergency procedures among team members to address any incidents swiftly.

By adhering to these best practices, you can significantly enhance the safety and efficiency of your fiber laser operations, ultimately leading to better outcomes in your projects.