How to Choose the Right Fiber Marking Machine for Your Business Needs

In today's manufacturing landscape, the demand for precision and efficiency has never been higher, leading businesses to seek advanced technologies that can enhance their production processes. A pivotal tool in this realm is the Fiber Marking Machine, which is renowned for its capability to produce high-quality engravings on a variety of materials. According to industry reports, the global market for fiber laser marking systems is expected to reach over $1 billion by 2026, driven by an increasing adoption across sectors like automotive, electronics, and aerospace. Such growth emphasizes the importance of selecting the right marking machine tailored to specific operational needs.

Choosing the right Fiber Marking Machine is not merely a matter of selecting an available option; it requires a comprehensive understanding of your business's unique requirements and the technology’s capabilities. As organizations increasingly prioritize traceability and branding, the versatility offered by fiber lasers — capable of engraving metal, plastic, and other surfaces — is becoming indispensable. Furthermore, research indicates that businesses utilizing advanced marking technologies can improve their production efficiency by up to 30%, making the right choice even more critical. This guide aims to equip you with the knowledge needed to make an informed decision, ensuring your business can reap the full benefits of fiber marking technology.

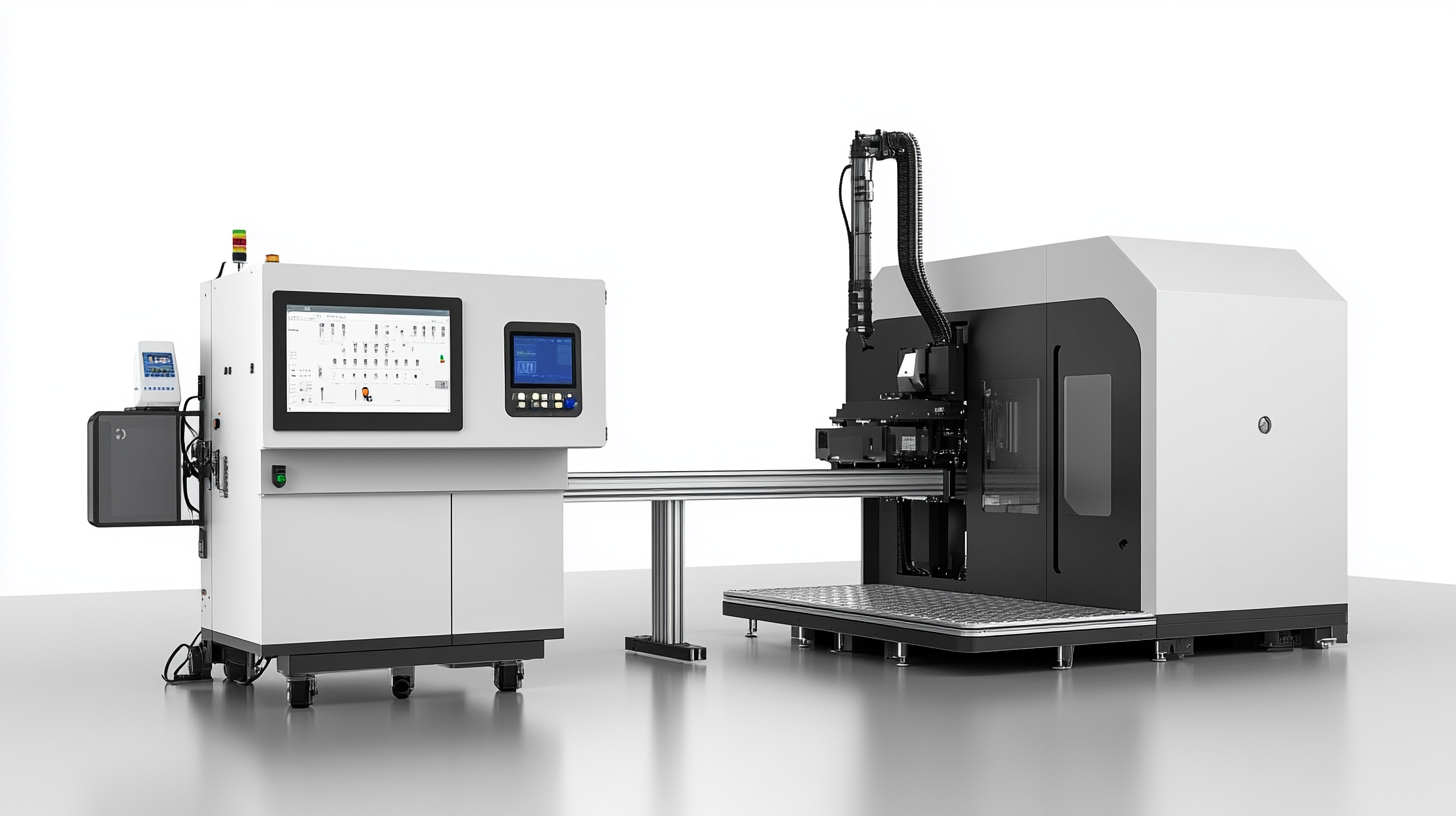

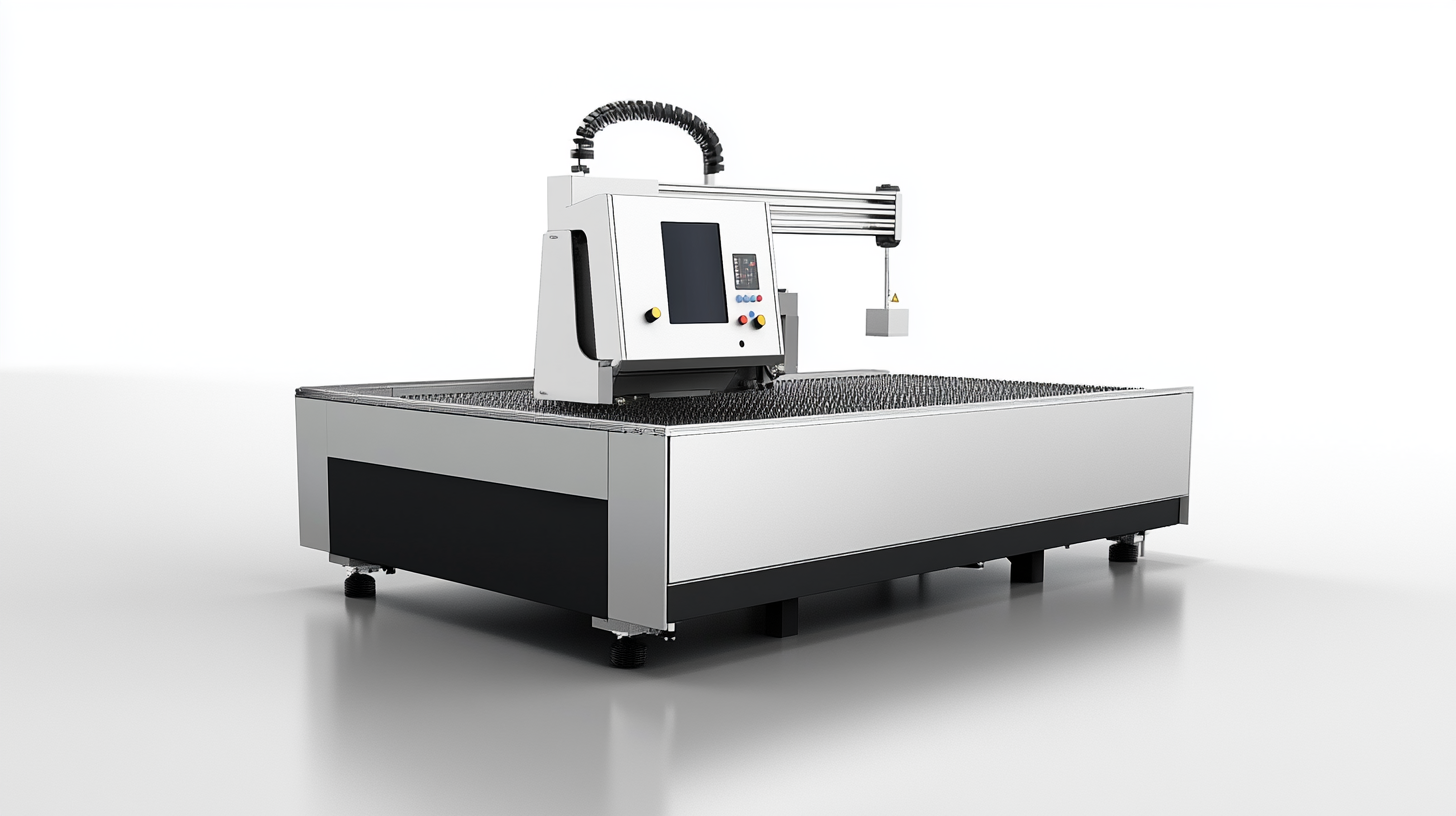

Understanding the Different Types of Fiber Marking Machines

When considering the right fiber marking machine for your business, it's essential to understand the different types available on the market. Fiber marking machines are increasingly popular due to their precision and efficiency in engraving materials like metals and plastics. Two primary types stand out: fiber laser engravers and diode laser machines. Fiber laser engravers, known for their high power and speed, are ideal for businesses requiring intricate designs and fast production rates. In contrast, diode lasers are often more cost-effective and suitable for lighter applications. The xTool F1 Ultra, a notable entry in this landscape, represents a convergence of technology with its 20W fiber and diode capabilities, making it an innovative choice for small laser business owners. This machine not only meets the needs of those just starting but also offers advanced features that can scale with a growing enterprise. As the global laser marking machine market is projected to exceed USD 5.8 billion by 2032, investing in a versatile fiber marking machine like the xTool F1 Ultra could position your business to take advantage of this booming sector while enhancing production efficiency.

Key Factors to Consider When Selecting a Fiber Marking Machine

When selecting a fiber marking machine for your business, there are several key factors to consider to ensure you make the right choice for your specific needs. Firstly, analyze the material you will be marking. Fiber laser machines are particularly effective for metals and some plastics, while other types may be more suited for different materials. Understanding the compatibility of the machine with your intended materials will greatly influence your efficiency and output quality.

Another important consideration is the machine’s power and speed capabilities. Depending on the volume of work and the level of detail required in your markings, you may need a machine with higher wattage for faster processing times. Additionally, assess the marking area size; if your products vary in dimensions, a machine with adjustable marking areas might be beneficial.

Furthermore, evaluate the technology and features that come with the fiber marking machine. Innovations such as user-friendly interfaces, integrated software for design, and maintenance requirements can significantly impact your operational efficiency. It’s also wise to consider the machine’s longevity and the availability of technical support. Investing in a reliable machine with good after-sales service can save time and resources in the long run, ensuring that your business runs smoothly and efficiently.

Assessing Your Business's Specific Marking Requirements

When selecting a fiber marking machine for your business, it's crucial to assess your specific marking requirements. Different industries may demand different specifications, so understanding your operational needs is the first step toward making the right choice. For example, if your business involves marking on specialized materials such as metals or plastics, ensure that the machine you choose can accommodate the necessary settings to handle those substrates effectively.

Furthermore, consider the scale and volume of your production. A machine that works efficiently for small batches may not be suitable for high-volume operations. In this context, it’s beneficial to evaluate the production speed and the clarity of the markings produced, as these factors will directly affect your overall productivity and quality control.

Additionally, the evolving landscape of technology means that new advancements in marking machines, such as AI-powered solutions, can enhance efficiency and precision. Staying abreast of the latest innovations can give your business a competitive edge while simplifying complex marking tasks. As seen in industries like pharmacovigilance where accurate marking can hold significant importance, integrating advanced technology can lead to better compliance and safety outcomes. Therefore, a thorough assessment of both current needs and future advancements is essential while selecting a fiber marking machine.

The Role of Budget in Choosing a Fiber Marking Machine

When selecting the right fiber marking machine for your business, it is crucial to consider your budget carefully. The cost of these machines can vary significantly based on their features, capabilities, and brand reputation. Knowing how much you are willing to invest will not only help narrow down your options but also ensure that you select a machine that meets your operational needs without overspending.

Investing in a budget-friendly fiber marking machine doesn’t mean you have to compromise on quality or functionality. Many excellent options are available that balance performance with affordability. You'll want to evaluate not just the initial purchase price but also the long-term operational costs, including maintenance and potential upgrades. By planning your budget thoughtfully, you can find a machine that serves well for engraving projects or small business tasks, ensuring you get the best value for your investment.

Additionally, consider the specific requirements of your business when setting your budget. For instance, if you plan to engage in heavier industrial applications, it may be worth investing more upfront in a robust machine that can handle increased workloads. Conversely, if your projects are more of a hobbyist nature, a more economical option may suffice. Understanding the role of your budget in this decision-making process will empower you to select the ideal fiber marking machine tailored to your needs.

Evaluating Supplier Reputation and Support Services

When selecting a fiber marking machine for your business, evaluating supplier reputation and support services is crucial. The reliability of the manufacturer often reflects the quality of their machines. Start by researching the supplier’s background; a long-standing presence in the industry typically indicates stability and expertise. Look for customer reviews and testimonials that provide insights into the performance of the machines and the level of customer satisfaction. A reputable supplier will have a proven track record of fulfilling their promises and maintaining product standards over time.

Moreover, support services play a vital role in ensuring a smooth operational experience with your fiber marking machine. Investigate the availability and responsiveness of their customer support team. A supplier that offers comprehensive technical support, including installation assistance and training, demonstrates their commitment to customer success. Additionally, consider whether they provide ongoing maintenance services and spare parts availability, as this can significantly reduce downtime in your production process. Companies that prioritize after-sales support often foster more profound partnerships, giving you peace of mind with your investment.