Choosing the Right Manufacturer for the Best Fiber Laser Marking Machine to Meet Your Global Needs

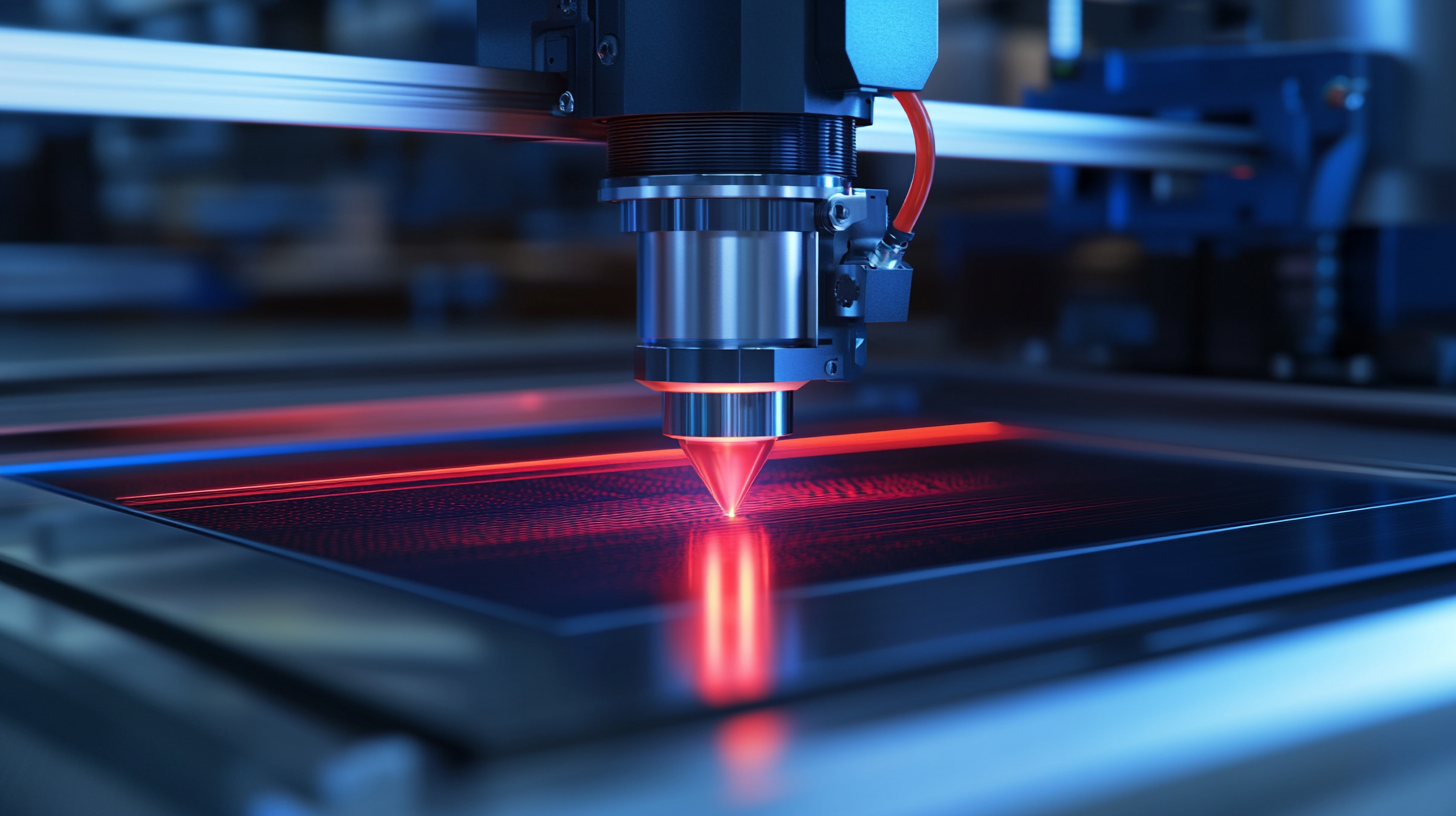

In the rapidly evolving landscape of industrial technologies, the demand for high-quality Fiber Laser Marking Machines has surged, driven by their precision and efficiency in various applications ranging from automotive to electronics. According to a recent industry report by Research and Markets, the global fiber laser market is projected to grow at a CAGR of over 10% through 2026, significantly propelled by advancements in laser technology and the increasing need for high-quality marking solutions. As businesses look to enhance their production capabilities, choosing the right manufacturer is crucial to ensure performance and reliability. This decision not only impacts operational efficiency but also plays a vital role in establishing a brand's presence in international markets. With Chinese manufacturers leading the charge in innovation and quality, it is essential to evaluate potential partners to harness the capabilities of fiber laser technology and meet global needs effectively.

In the rapidly evolving landscape of industrial technologies, the demand for high-quality Fiber Laser Marking Machines has surged, driven by their precision and efficiency in various applications ranging from automotive to electronics. According to a recent industry report by Research and Markets, the global fiber laser market is projected to grow at a CAGR of over 10% through 2026, significantly propelled by advancements in laser technology and the increasing need for high-quality marking solutions. As businesses look to enhance their production capabilities, choosing the right manufacturer is crucial to ensure performance and reliability. This decision not only impacts operational efficiency but also plays a vital role in establishing a brand's presence in international markets. With Chinese manufacturers leading the charge in innovation and quality, it is essential to evaluate potential partners to harness the capabilities of fiber laser technology and meet global needs effectively.

Key Factors to Consider When Choosing a Fiber Laser Marking Machine Manufacturer

When selecting a fiber laser marking machine manufacturer, several key factors come into play that can significantly influence the success of your investment. First and foremost, assess the manufacturer’s experience and expertise in the industry. A seasoned manufacturer will not only provide high-quality products but also offer valuable insights into the latest technology and trends in fiber laser marking. Look for companies with a robust track record of delivering reliable machines and technical support to their clients.

When selecting a fiber laser marking machine manufacturer, several key factors come into play that can significantly influence the success of your investment. First and foremost, assess the manufacturer’s experience and expertise in the industry. A seasoned manufacturer will not only provide high-quality products but also offer valuable insights into the latest technology and trends in fiber laser marking. Look for companies with a robust track record of delivering reliable machines and technical support to their clients.

Additionally, consider the range of products and customization options available. Your specific marking needs may vary based on application, materials, and production volume. Therefore, a manufacturer that offers a diverse lineup of machines and the flexibility to tailor solutions will better meet your global requirements. Finally, don’t overlook customer service and support. A responsive and knowledgeable support team is crucial for maintaining your equipment and troubleshooting issues as they arise, ensuring smooth operation and minimal downtime.

Evaluating Manufacturer Experience and Expertise in Fiber Laser Technology

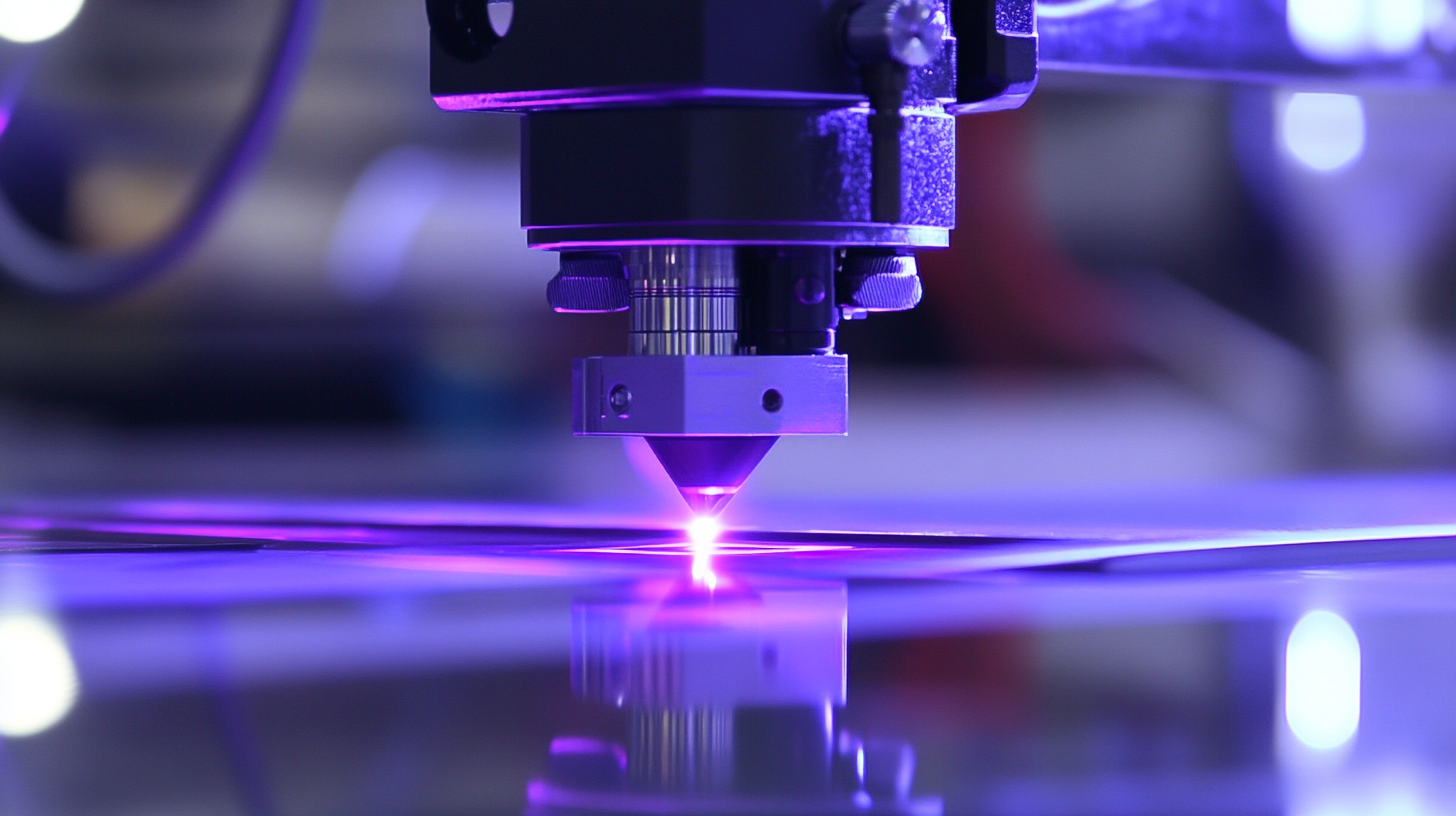

When selecting a manufacturer for fiber laser marking machines, evaluating their experience and expertise in fiber laser technology is paramount. According to a report from MarketsandMarkets, the global fiber laser market is projected to reach $4.3 billion by 2025, growing at a CAGR of over 9% from 2020. This growth underscores the importance of partnering with a manufacturer that not only understands the technology but has also contributed to its advancement. A seasoned manufacturer can provide insights into the latest trends and innovations, ensuring that the machines meet the evolving demands of various industries.

Additionally, the technical prowess of a manufacturer can significantly impact the performance and reliability of fiber laser marking systems. A study from Research and Markets highlights that precision applications, including automotive and aerospace sectors, require machines that can operate under strict performance parameters. Manufacturers with a proven track record in successful project implementations will possess the knowledge and skills necessary to fulfill these requirements. Choosing a manufacturer with extensive experience can lead to improved operational efficiency and reduced downtime, ultimately resulting in a better return on investment for laser marking solutions.

Understanding Global Standards and Compliance for Fiber Laser Marking Machines

When selecting a manufacturer for fiber laser marking machines, it is crucial to understand the global standards and compliance requirements that guide the industry. Different regions have their own regulatory frameworks that manufacturers must adhere to, ensuring the safety, quality, and efficiency of their products. For instance, certifications such as CE in Europe and FDA compliance in the United States showcase a manufacturer’s commitment to meeting the necessary health and safety standards. This compliance not only protects the end-users but also enhances the credibility of the manufacturers in the global market.

Moreover, understanding these standards helps businesses select machines that are compatible with their operational needs. For example, a company operating in multiple countries may require laser marking equipment that can meet the diverse regulatory requirements of each locale. Moreover, adherence to global standards can facilitate smoother certification processes when expanding into new markets, thereby addressing any potential legal hurdles associated with non-compliance. By prioritizing manufacturers that embrace these standards, businesses can ensure they invest in fiber laser marking machines that are both reliable and compliant, ultimately supporting their global expansion goals.

Analyzing Customer Support and Service Options from Manufacturers

When selecting a fiber laser marking machine, one of the most critical factors to consider is the customer support and service options provided by the manufacturer. A strong support system ensures that any operational challenges can be quickly addressed, minimizing downtime and enhancing productivity. It is essential to assess whether the manufacturer offers comprehensive technical support, including assistance with installation and ongoing maintenance. In addition, consider the availability of training resources for your team to ensure they are well-versed in operating the equipment efficiently.

Another key aspect to examine is the responsiveness of customer service. Manufacturers should offer multiple communication channels, such as phone, email, and live chat, allowing you to reach out for assistance easily. Quick response times can significantly impact your overall experience, especially during critical times when immediate help is needed. Furthermore, understanding the warranty and service terms can help you make an informed decision, ensuring that you have reliable support long after your initial purchase. By prioritizing these service-oriented features, you can choose a manufacturer that aligns with your global operational needs and fosters a productive partnership.

Choosing the Right Manufacturer for the Best Fiber Laser Marking Machine to Meet Your Global Needs - Analyzing Customer Support and Service Options from Manufacturers

| Manufacturer Type | Customer Support Options | Technical Support Availability | Average Response Time | Warranty Period | After-Sales Service |

|---|---|---|---|---|---|

| International Manufacturer | 24/7 Phone Support, Email Assistance | Available | Within 2 hours | 2 Years | On-Site Support, Remote Assistance |

| Local Manufacturer | Business Hours Chat, Email Support | Limited Hours | Within 24 hours | 1 Year | In-House Training, Online Resources |

| Regional Manufacturer | Email Support, Limited Chat | Available on Weekdays | Within 48 hours | 18 Months | Phone Support, FAQ Section |

Comparing Costs versus Value: What to Look for in Fiber Laser Machines

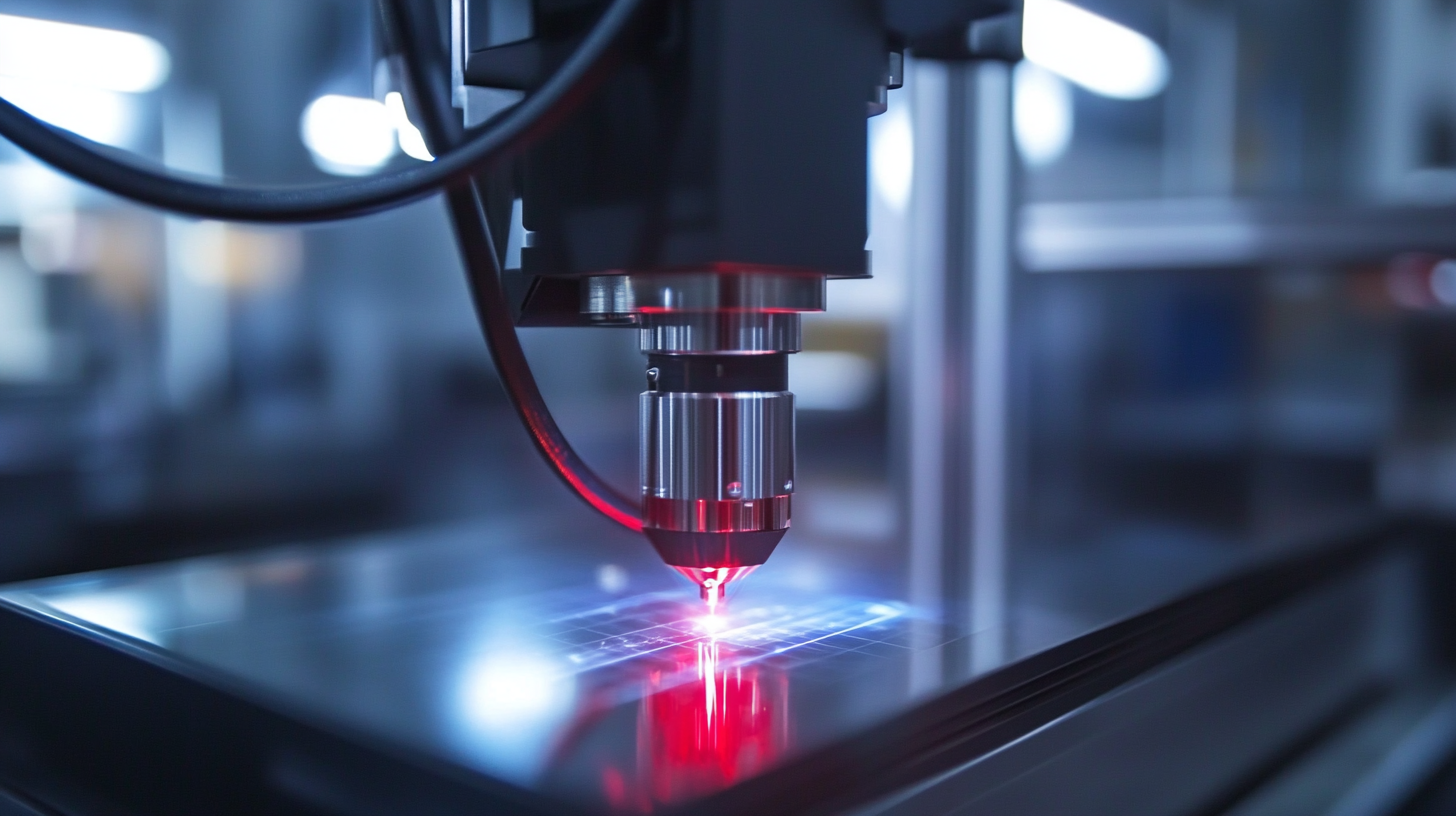

When selecting a fiber laser marking machine, it's essential to balance costs against the value offered. While it might be tempting to opt for the lowest-priced option available, this could lead to compromises in quality, durability, and performance. A lower initial investment may result in higher operational costs over time due to increased maintenance, downtime, or the need for premature replacements. Therefore, understanding the long-term implications and benefits of investing in a reputable manufacturer can provide significant advantages.

When evaluating fiber laser machines, consider not only the purchase price but also the features and capabilities they offer. Look for machines that provide ease of use, precision, and reliability, as these factors greatly enhance productivity. Additionally, consider after-sales support, warranty options, and availability of replacement parts from the manufacturer. Investing in a machine that delivers consistent results and lasting performance can ultimately prove to be more cost-effective, making it an essential factor in your purchasing decision.