Why Are Die Casting Molds Essential for Manufacturing Success?

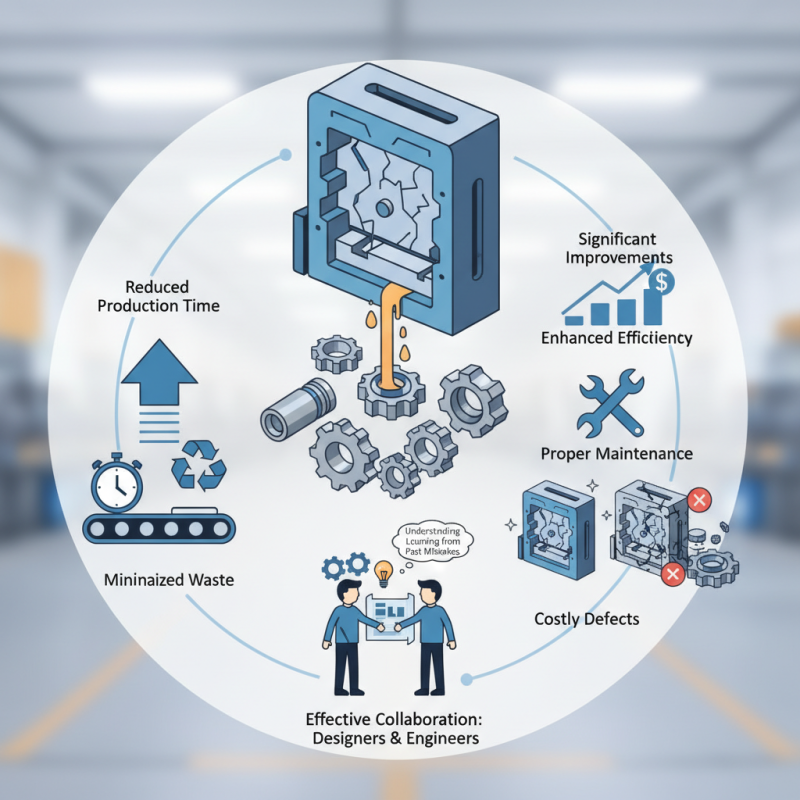

Die Casting Molds play a crucial role in the manufacturing industry. These molds shape metal into precise components. Their importance cannot be overstated. A well-designed mold reduces production time. It also minimizes waste, enhancing efficiency.

When manufacturers invest in quality Die Casting Molds, they often see significant improvements. However, many overlook the necessity of proper maintenance. This neglect can lead to costly defects. The mold’s precision can fade, impacting the final product.

Effective collaboration between designers and engineers is vital. Communication ensures that the Die Casting Molds meet production needs. Yet, we often see gaps in this collaboration. Understanding the nuances of these molds can lead to better outcomes. Learning from past mistakes is essential for progress. Emphasizing the role of Die Casting Molds can drive a manufacturing firm’s success.

The Role of Die Casting Molds in the Manufacturing Process

Die casting molds play a crucial role in the manufacturing process. These molds are designed to create parts with high precision and efficiency. According to the North American Die Casting Association, the die casting industry generates over $4 billion annually. This indicates a strong market demand for quality molds that ensure consistency and durability.

In die casting, the mold quality directly affects production speed and cost. A well-designed mold can reduce cycle time by 15% or more. However, the production process can face challenges. For example, wear and tear on molds can lead to defects in the final product. A study from the American Foundry Society highlighted that about 30% of production issues stem from mold-related factors. Manufacturers need to invest in regular maintenance to avoid these pitfalls.

The precision of die casting molds also impacts material efficiency. Accurate molds minimize wastage, which is essential in an industry seeking sustainability. Industry reports reveal that up to 20% of raw material is lost in poor mold designs. This not only affects the bottom line but also the environment. Reducing material loss should be a priority for manufacturers aiming for both economic and ecological success.

Understanding the Types of Die Casting Molds Available

Die casting molds play a crucial role in manufacturing success. They ensure precision and efficiency in the production process. There are several types of die casting molds available, each designed for specific applications. Understanding these types is key to choosing the right mold for your project.

One common type is the single cavity mold. It produces one part per cycle. Ideal for low-volume production, it is cost-effective. However, it may slow down high-demand projects. Multi-cavity molds, on the other hand, can produce several parts in one go. This can significantly increase production rates. According to industry reports, multi-cavity molds can boost efficiency by up to 50%.

Tips: Always evaluate your production needs before selecting a mold type. It’s vital to consider volume and complexity. Balancing costs and production speed can impact your overall success. Investing in high-quality molds, despite their initial expense, can yield better long-term results.

Another type is the hot chamber mold. This is suitable for metals with low melting points, such as zinc. It allows for faster cycles. However, it is not compatible with high-temperature metals. Cold chamber molds are more versatile for diverse materials but involve more complex setups. Each option has its pros and cons. Choose wisely to align with your desired output quality.

Key Factors Influencing Die Casting Mold Design

Die casting molds are crucial for the manufacturing process. Their design directly impacts production efficiency and product quality. Key factors influence how these molds are created. Material selection is one of them. Choosing the right metal affects durability. A weak mold may break easily, causing costly delays.

Another important factor is the mold design itself. Precision in design minimizes defects. Complex shapes need careful planning. Rushing this stage can lead to problems. Molds must also accommodate thermal expansion. If not, they may warp or fit poorly, leading to wasted materials and time.

The cooling system within the mold is vital too. A well-designed cooling system ensures consistent temperature control. Insufficient cooling can result in uneven product quality. It's a delicate balance. Manufacturers often overlook these details. Regular assessments probably reveal areas needing improvement. Investing in better designs leads to greater long-term success.

Benefits of Using High-Quality Die Casting Molds

High-quality die casting molds play a crucial role in manufacturing success. They directly influence the quality of the finished product. A well-designed mold ensures precision and consistency in each casting. This leads to reduced waste and lower production costs. When molds are durable, they withstand the rigors of repeated use. This durability increases productivity in the long run.

Using high-quality molds can also improve the overall performance of the parts produced. Precision molds minimize defects, which can save time and resources. On the flip side, poor-quality molds often require frequent replacements. This unpredictability can stall production. It raises costs and affects scheduling. Investing in superior molds may seem pricey initially, but the advantages can outweigh the costs.

Moreover, integrating advanced materials in mold production can enhance efficiency. This approach can result in faster cooling times and better surface finishes. However, it is essential to evaluate the manufacturing process regularly. Ignoring this can lead to inefficiencies. A continuous assessment of mold performance can guide necessary adjustments. This reflection is key to maintaining high standards in die casting production.

Impact of Die Casting Molds on Production Efficiency and Cost

Die casting molds play a crucial role in manufacturing. They directly impact production efficiency and cost. According to a recent industry report, well-designed molds can increase production rates by up to 30%. This efficiency translates to lower unit costs, which is vital for competitive pricing.

The initial investment in die casting molds can be significant. Some reports estimate costs can reach thousands of dollars. However, the long-term savings are substantial. High-quality molds last longer and require fewer repairs. An analysis showed that the right mold can reduce cycle times by 25%. This reduction not only accelerates output but also minimizes waste.

Yet, not all molds are created equal. Many manufacturers overlook the importance of mold maintenance. Regular checks are essential to ensure optimal performance. Neglecting mold care can lead to defects and rework. Inefficiency in this area can erase any cost savings. Investing in quality molds while maintaining them is a reflection of thoughtful manufacturing practice.