7 Essential Tips for Choosing the Best Fiber Laser Enclosure for Your Business Needs

In today's fast-paced manufacturing landscape, the selection of the right equipment is paramount for achieving efficiency and safety. One vital component that often goes overlooked is the Fiber Laser Enclosure, which plays a critical role in safeguarding both operators and machinery during laser cutting processes. As businesses aim to meet the demands of a global market, especially in the context of "Strength in Manufacturing, Made in China, Exporting Worldwide", understanding how to choose the best Fiber Laser Enclosure becomes essential. This enclosure not only protects personnel from harmful laser emissions but also enhances the longevity of the laser systems by reducing environmental contamination.

In this blog, we will explore seven essential tips to guide you in selecting the most suitable Fiber Laser Enclosure that aligns with your specific business needs, ensuring productivity and compliance with safety regulations.

Understanding the Importance of Fiber Laser Enclosures for Safety and Efficiency

Fiber laser enclosures play a crucial role in ensuring safety and efficiency in laser cutting and engraving operations. According to the International Laser Safety Standards, the use of protective enclosures can significantly reduce the risk of laser radiation exposure to operators, which is essential for maintaining a safe working environment. Reports indicate that nearly 30% of workplace accidents related to laser operations stem from inadequate safety measures, emphasizing the importance of investing in reliable enclosures.

Moreover, fiber laser enclosures contribute to operational efficiency by minimizing environmental disturbances and maintaining optimal working conditions. A study by the Laser Institute of America found that enclosures can help reduce ambient noise levels by up to 20 dB, enhancing comfort for workers and ensuring fewer distractions during intense work sessions. Additionally, these enclosures prevent contamination from dust and debris, which can compromise the quality of laser cuts and increase maintenance costs. By selecting the right enclosure, businesses not only prioritize safety but also enhance productivity, leading to better overall performance.

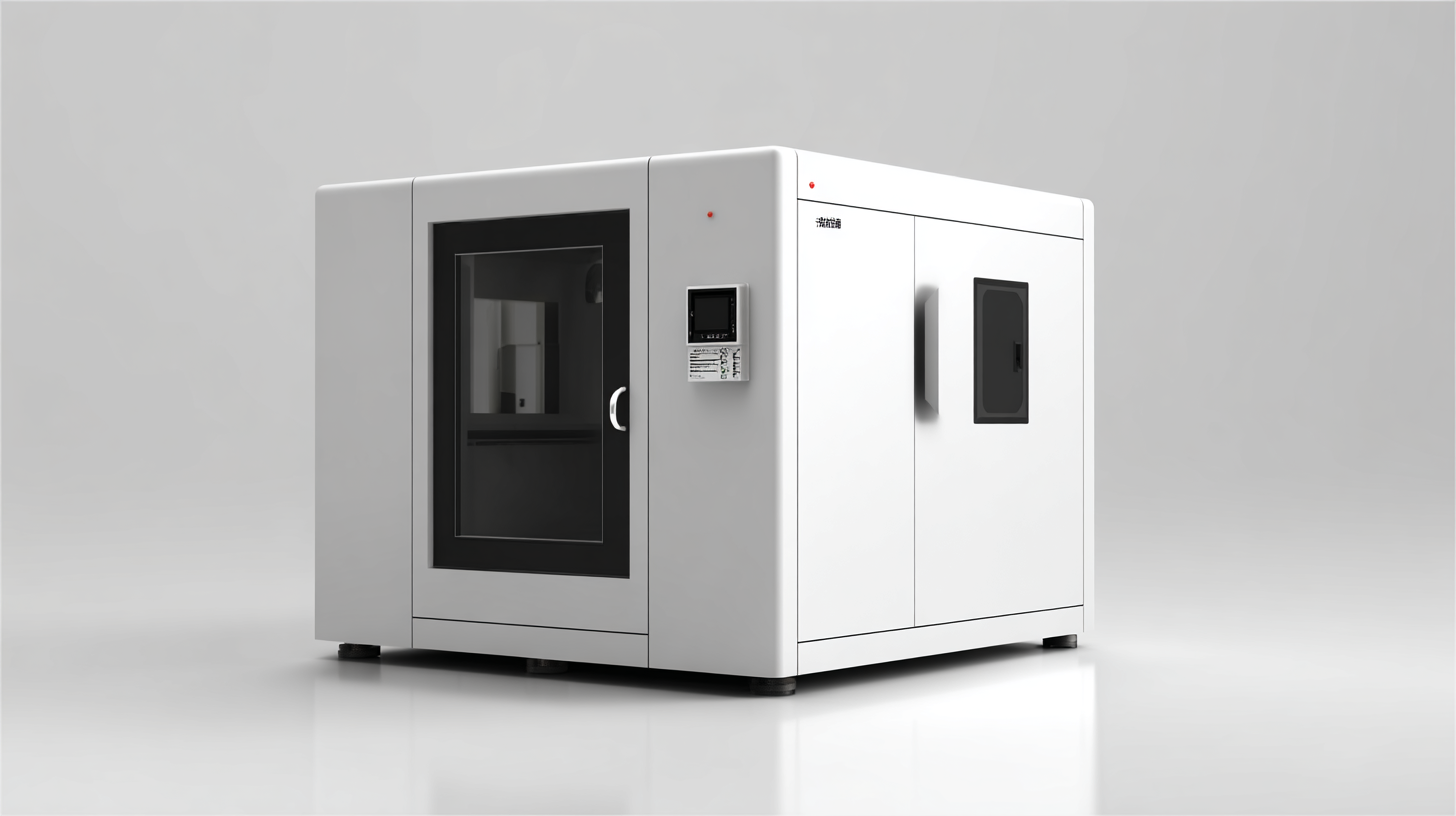

Key Features to Look for in a Quality Fiber Laser Enclosure

When selecting a fiber laser enclosure, several key features should be prioritized to ensure the safety and efficiency of your operations.

First and foremost, consider the material used in the construction of the enclosure. High-quality enclosures are typically crafted from robust materials that can withstand heat and potential impacts, ensuring durability and longevity.

Look for enclosures with proper insulation to minimize sound and protect against hazardous fumes, as a well-insulated enclosure offers a safer working environment for employees.

Another essential feature is the transparency of the enclosure. A thick safety glass or polycarbonate panel allows operators to monitor the laser work without exposing themselves to harmful emissions.

Additionally, effective ventilation systems are vital in maintaining optimal air quality inside the enclosure. Good ventilation not only helps in dissipating heat but also prevents the buildup of hazardous gases emitted during the laser cutting process.

By focusing on these key features, businesses can select a fiber laser enclosure that supports their operational needs while prioritizing safety.

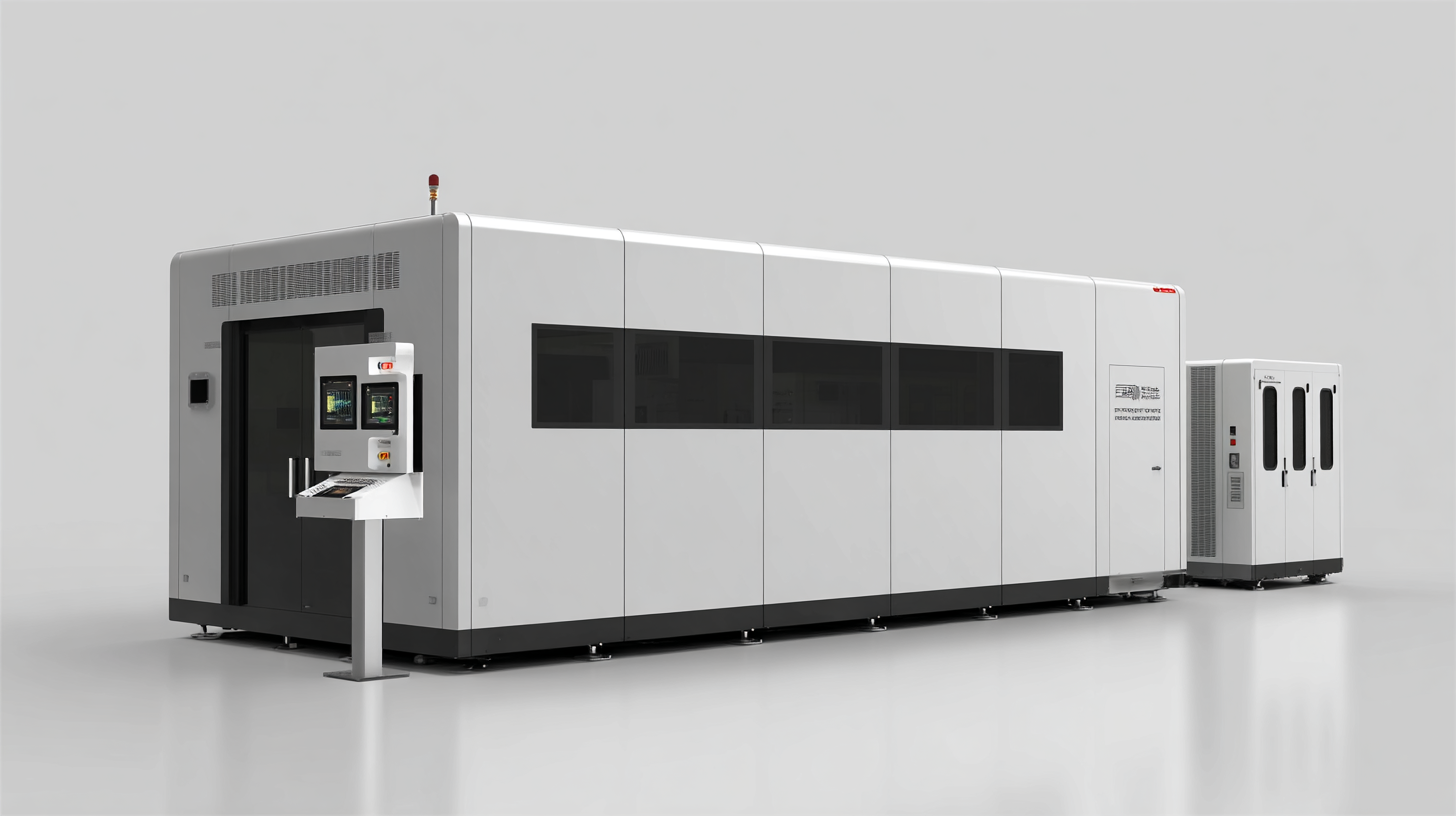

Evaluating Size and Space Requirements for Your Business Setup

When selecting a fiber laser enclosure for your business, evaluating size and space requirements is crucial. The dimensions of the enclosure should align with your workflow and operational layout. It's essential to measure not only the physical space available but also consider the movement of materials and personnel around the workspace. A compact and efficiently designed enclosure can significantly enhance productivity by minimizing unnecessary movements and bottlenecks.

Moreover, it's important to factor in the potential growth of your business. As industries like HVAC are projected to expand significantly, alongside markets such as diesel generators, your space might need to accommodate future equipment or expanded operations. This foresight ensures that your laser enclosure can adapt to changes without necessitating a complete redesign of your setup. By prioritizing size and space considerations, you can create a robust, flexible work environment that meets both current and future needs.

Comparing Materials and Build Quality of Different Enclosure Options

When selecting the ideal fiber laser enclosure for your business, it's critical to compare the materials and build quality of different options. Recent industry reports indicate that approximately 70% of users experience efficiency gains when utilizing enclosures made from high-grade materials like aluminum and steel. These materials not only enhance durability but also improve the safety and performance of your laser operations. Aluminum, for instance, offers a lightweight yet sturdy alternative that ensures longevity while being less prone to corrosion.

Moreover, the build quality of an enclosure can significantly influence its effectiveness in containing hazardous fumes and debris generated during laser cutting processes. According to a 2022 study by the Laser Processing Association, enclosures that feature reinforced panels and superior sealing can reduce airborne contaminants by up to 85%. This not only ensures compliance with health and safety regulations but also enhances the overall working environment, thereby improving employee productivity. As businesses increasingly prioritize safety and efficiency, carefully considering the enclosure’s materials and build quality becomes paramount in making an informed choice.

Comparison of Different Fiber Laser Enclosure Materials

Assessing Compliance with Safety Standards and Regulations for Lasers

When selecting a fiber laser enclosure, compliance with safety standards is paramount. According to the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA), laser safety is governed by strict regulations to prevent accidents and injuries. For instance, Class 1 laser enclosures are designed to contain any potentially harmful emissions, thus safeguarding operators and bystanders. Ensuring that your enclosure meets these regulatory requirements not only protects your workforce but can also mitigate legal liabilities associated with workplace accidents.

Furthermore, the International Electrotechnical Commission (IEC) standard IEC 60825-1 outlines specific requirements for the safety of laser products. This standard emphasizes the importance of proper shielding, interlocks, and emergency shut-off systems in laser enclosures. A recent report by the Laser Institute of America indicates that over 90% of reported laser-related injuries could have been prevented with adequate safety measures in place. Organizations must prioritize the evaluation of fiber laser enclosures against these safety benchmarks to promote a secure working environment, ultimately fostering productivity and efficiency in laser applications.