Mastering the Art of Fiber Laser Marking for Precise Branding and Identification

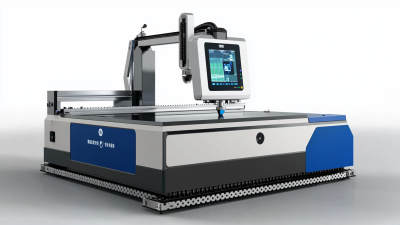

The demand for precise branding and identification solutions in various industries has significantly increased, leading to the growing popularity of Fiber Laser Markers. According to a recent report by Research and Markets, the global laser marking market is projected to reach $4.72 billion by 2026, with fiber laser marking taking a substantial share due to its efficiency, precision, and versatility. Fiber lasers not only achieve high-quality results on a wide range of materials but also operate at reduced maintenance costs and energy consumption compared to traditional marking systems. In an era where brand differentiation and product traceability are paramount, mastering fiber laser marking techniques is essential for businesses looking to maintain a competitive edge. By exploring alternative applications and technologies, organizations can enhance their branding efforts while ensuring compliance with industry standards.

Understanding the Basics of Fiber Laser Marking Technology

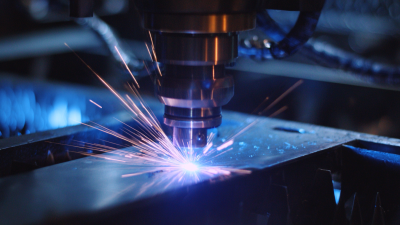

Fiber laser marking technology has emerged as a precise and efficient method for branding and identification across various industries. This technology utilizes fiber-optic cables to generate high-intensity laser beams that can etch intricate designs or data onto materials such as metals, plastics, and ceramics. According to a report by MarketsandMarkets, the global fiber laser market is projected to grow from $1.06 billion in 2021 to $2.66 billion by 2026, at a compound annual growth rate (CAGR) of 19.1%. This rapid growth is driven by the increasing demand for high-quality marking solutions that can enhance product traceability and authority in competitive markets.

One of the key advantages of fiber laser marking is its ability to produce permanent, high-resolution marks that are resistant to wear and corrosion. This is particularly important for industries like aerospace, automotive, and electronics, where durability and compliance with strict regulations are paramount. A study by Allied Market Research states that approximately 30% of manufacturers are turning to laser marking technologies to meet their branding and serialization needs, highlighting the shift towards innovative solutions that not only improve product identification but also reinforce brand integrity. With advancements in fiber laser technology, companies are now able to achieve unparalleled precision, making it an essential tool for effective branding in an increasingly globalized marketplace.

The Applications of Fiber Laser Marking in Various Industries

Fiber laser marking has emerged as a pivotal technology across various industries due to its precision and versatility. The fiber laser marking market is projected to reach approximately $5.2 billion by 2025, growing at a CAGR of around 7.2% from 2020 to 2025. This growth can be attributed to the increasing demand for durable and high-quality marking solutions in sectors such as automotive, electronics, and medical devices. The ability of fiber lasers to create permanent, high-contrast markings on a variety of materials makes them ideal for branding and product identification.

In the aerospace and automotive industries, where traceability is crucial, fiber laser marking ensures that components are easily identifiable and comply with stringent regulatory requirements. The technology further proves its worth in the electronics sector, where small, detailed marks are essential for product identification and traceability. With the advent of Industry 4.0, manufacturers are increasingly adopting fiber laser solutions to enhance operational efficiency and ensure product authenticity. As the demand for high-speed and precise marking continues to rise, fiber laser marking stands out as a key player in the future of industrial identification and branding.

Applications of Fiber Laser Marking in Various Industries

Benefits of Fiber Laser Marking for Branding and Product Identification

Fiber laser marking has emerged as a cutting-edge technology for branding and product identification, offering unparalleled benefits that are reshaping the manufacturing landscape. One of the most notable advantages is the precision it provides. According to a report by MarketsandMarkets, the global fiber laser market is projected to reach $4.29 billion by 2026, reflecting a growing trend towards high-accuracy marking solutions. This technology allows for intricate designs and texts to be marked on various materials, ensuring that brand logos and identifiers are both visible and durable.

Moreover, fiber laser marking enhances product traceability, which is critical in today's market where safety and authenticity are paramount. A study by Research and Markets indicates that the adoption of advanced marking technologies can reduce product misidentification by over 60%. This not only supports compliance with regulatory standards but also fosters consumer trust. As businesses increasingly prioritize transparency and accountability, fiber laser marking stands out as a reliable solution, enabling brands to connect with consumers through clear and permanent identification that withstands time and environmental challenges.

Mastering the Art of Fiber Laser Marking for Precise Branding and Identification - Benefits of Fiber Laser Marking for Branding and Product Identification

| Feature | Description | Benefits |

|---|---|---|

| Precision | Fiber laser marking provides high-resolution marking capabilities, ensuring that logos and text are clear and sharp. | Enhances brand recognition and product identification. |

| Durability | Marks made by fiber lasers are resistant to wear and tear, chemicals, and environmental conditions. | Ensures longevity of branding efforts across products and components. |

| Speed | Fiber lasers can mark quickly, increasing production efficiency without sacrificing quality. | Reduces downtime and boosts overall productivity in manufacturing processes. |

| Versatility | These lasers can mark on various materials including metals, plastics, and ceramics. | Allows for branding across a diverse range of products. |

| Cost-Effectiveness | Minimal maintenance and consumables required make fiber lasers a cost-effective solution. | Reduces operational costs while maintaining high-quality output. |

Top Reasons to Choose Fiber Laser Marking Over Traditional Methods

Fiber laser marking has emerged as a game-changer in branding and identification, offering numerous advantages over traditional methods. One of the primary reasons to choose fiber lasers is their precision. Utilizing a highly focused beam, fiber lasers can create intricate designs and text with incredible accuracy, which is essential for maintaining brand integrity and clarity in identification. This level of precision ensures that even the smallest details, such as logos or serial numbers, are sharp and legible, enhancing the overall quality of the marked product.

Fiber laser marking has emerged as a game-changer in branding and identification, offering numerous advantages over traditional methods. One of the primary reasons to choose fiber lasers is their precision. Utilizing a highly focused beam, fiber lasers can create intricate designs and text with incredible accuracy, which is essential for maintaining brand integrity and clarity in identification. This level of precision ensures that even the smallest details, such as logos or serial numbers, are sharp and legible, enhancing the overall quality of the marked product.

Another significant benefit is the speed and efficiency of fiber laser marking. Unlike traditional methods that may require more time to set up and execute, fiber lasers can operate at a fraction of the time. This means quicker turnaround times for production and the ability to scale operations without sacrificing quality. Additionally, fiber lasers are versatile and can work on a variety of materials, including metals, plastics, and composites, making them suitable for a wide range of applications. This adaptability, combined with reduced maintenance requirements, makes fiber laser marking a smart investment for businesses looking to streamline their branding processes while ensuring durability and precision.

Tips for Optimizing Fiber Laser Marking for Maximum Precision and Quality

Fiber laser marking has become an essential tool for businesses aiming to enhance their branding and facilitate precise identification. To truly optimize fiber laser marking, understanding a few key tips can make a significant difference in achieving maximum precision and quality.

First, selecting the right parameters is critical. Adjust the laser power, speed, and focus to suit the material you are working with. For instance, lower speeds with higher power often result in deeper marks on metals, while faster settings may be more appropriate for delicate materials. Conduct trial runs to determine the optimal settings that yield the best results on your specific substrates.

Another vital tip is to maintain the cleanliness of both the laser lens and the material surface. Dust, fingerprints, or other contaminants can adversely affect the marking quality. Regular inspections and cleanings ensure that the laser beam remains focused and that the markings are crisp and clear. Furthermore, using appropriate marking techniques such as vector engraving or raster scanning can enhance the final output, leading to enhanced brand visibility and product identification.

Related Posts

-

Ultimate Guide to Choosing the Right Fiber Marking Laser for Your Business Needs

-

Challenges in Selecting the Right Laser Part Marking Machinery

-

Understanding Export Compliance for Desktop Fiber Laser Marking Machines in Global Markets

-

Unlocking Precision and Efficiency with Advanced Desktop Fiber Laser Marking Solutions

-

The Ultimate Guide to Choosing the Best Desktop Fiber Laser Marking Machine for Your Business Needs

-

Revolutionizing Production Efficiency with Innovative Fiber Laser Marking Machines