Revolutionizing Manufacturing: How Fiber Marking Machines Enhance Precision and Efficiency in Industrial Applications

In today's competitive industrial landscape, precision and efficiency have become paramount for manufacturers striving to optimize their operations. Fiber Marking Machines are at the forefront of this transformation, offering advanced solutions that enhance both the accuracy and speed of marking processes. According to a report by MarketsandMarkets, the global laser marking market is projected to reach USD 3.1 billion by 2026, driven largely by the increasing demand for high-quality marking and engraving in various sectors, including automotive, aerospace, and electronics. The adoption of Fiber Marking Machines has been particularly notable, as they provide superior versatility and minimal maintenance compared to traditional marking systems. This shift not only improves production workflows but also ensures compliance with stringent industry standards, ultimately leading to reduced operational costs and improved product traceability. As the manufacturing sector continues to evolve, embracing these innovative technologies will be crucial for companies aiming to maintain a competitive edge.

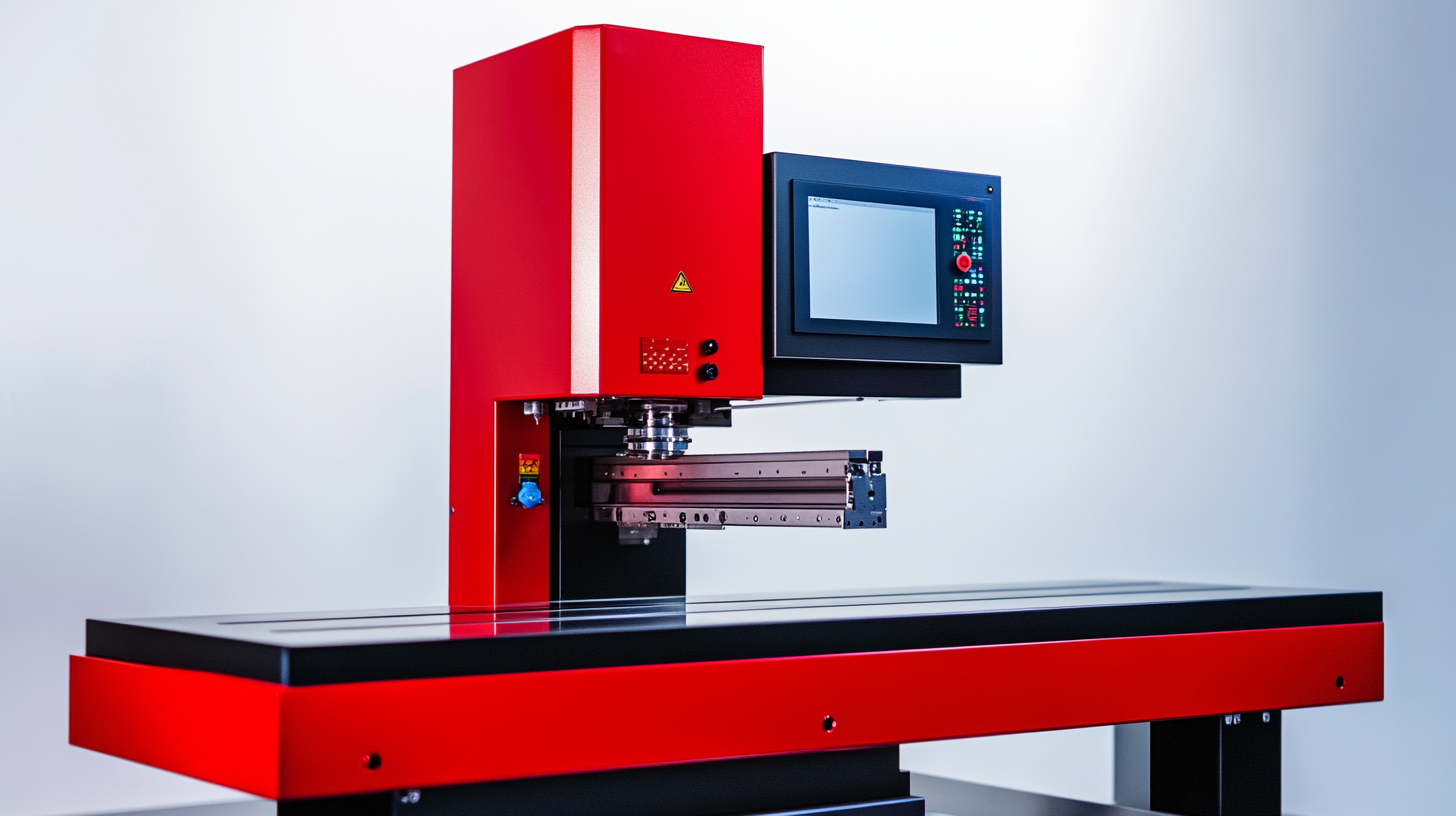

The Impact of Fiber Marking Technology on Manufacturing Precision

Fiber marking technology has emerged as a transformative force in the manufacturing sector, significantly enhancing precision and efficiency. As industries increasingly embrace automation, the need for reliable and accurate part marking has become paramount. Fiber marking machines, renowned for their exceptional precision, are now integral to the production process, especially in high-stakes environments like medical device manufacturing. The advancements in optical fibers and laser technology ensure that these machines deliver consistent and precise markings, which are crucial for tracking and compliance.

The global market for fiber lasers is anticipated to grow substantially, reflecting the widespread adoption of this technology. With projections estimating a rise from USD 7.7 billion in 2024 to USD 12.8 billion by 2029, it's clear that manufacturers recognize the value fiber marking machines bring to their operations. The enhanced beam characteristics and efficiency of ultrafast lasers further contribute to this trend, allowing for quicker production times and improved marking quality on various materials. As companies strive for greater efficiency and precision, the integration of fiber marking technology will play a vital role in reshaping the future of manufacturing.

Impact of Fiber Marking Technology on Manufacturing Precision

Key Advantages of Fiber Marking Machines Over Traditional Methods

Fiber marking machines have emerged as a game-changer in the manufacturing sector, outperforming traditional marking methods in several key areas. One significant advantage is their precision; according to a recent report by Smithers Pira, laser marking technology achieves accuracy levels that can be as high as 30 microns, ensuring detailed markings that remain clear even after extensive handling. This level of precision is crucial for industries requiring stringent traceability, such as aerospace and automotive sectors, where every detail matters to comply with safety and quality standards.

Moreover, the efficiency of fiber marking machines is remarkable. Research conducted by Technavio indicates that the adoption of laser marking solutions can increase production speeds by up to 50% compared to conventional methods like dot peen or mechanical engraving. This efficiency not only reduces operational costs but also allows manufacturers to meet high-volume demands more effectively. Additionally, the non-contact nature of fiber lasers minimizes the risk of material damage, further enhancing the overall productivity of industrial operations.

In addition to these benefits, fiber marking machines are renowned for their reduced maintenance requirements. Unlike traditional marking equipment, which may require frequent calibration and repairs, fiber lasers have a longer lifespan and lower upkeep costs. A report from MarketsandMarkets highlights that the fiber laser market is projected to grow from $3.8 billion in 2021 to $7.1 billion by 2026, underlining a significant shift in industry preference towards more efficient and reliable marking solutions.

Current Market Trends: The Demand for High-Precision Marking Solutions

In recent years, the demand for high-precision marking solutions has witnessed a significant surge, driven largely by advancements in manufacturing technologies and an increased focus on product traceability. According to a report from MarketsandMarkets, the global market for industrial marking solutions is expected to reach USD 5 billion by 2025, growing at a compound annual growth rate (CAGR) of 7.5%. This growth is primarily fueled by industries such as automotive, electronics, and pharmaceuticals, which require meticulous marking for regulatory compliance and quality assurance.

Fiber marking machines, in particular, have become pivotal in meeting these high precision demands. Unlike traditional marking methods, fiber lasers offer superior engraving quality and speed, making them ideal for a variety of materials including metals, plastics, and ceramics. A study conducted by ResearchAndMarkets indicated that the fiber laser marking segment alone could experience a CAGR of 8.2% from 2021 to 2026. With such robust growth metrics, it is evident that manufacturers are increasingly investing in these advanced marking technologies to enhance their operational efficiency and maintain competitive advantage in an ever-evolving market landscape.

Case Studies: Success Stories of Fiber Marking in Industrial Applications

The adoption of fiber marking machines in industrial applications has led to notable advancements in marking precision and efficiency, as highlighted by several case studies across various sectors. For instance, in the automotive industry, a major manufacturer reported a 30% reduction in marking time after integrating fiber lasers into their production line. This technology allowed for real-time adjustments to marking parameters, which not only increased production speed but also significantly improved the quality of markings, ensuring that each component adhered to stringent regulatory standards.

In the electronics sector, a leading smartphone manufacturer leveraged fiber marking machines to enhance traceability in their supply chain. According to a report by MarketsandMarkets, the traceability market is projected to reach $20 billion by 2025, driven in part by technologies such as fiber marking that facilitate better inventory management and compliance. This particular case study revealed that implementing fiber marking reduced errors in component identification by over 25%, thus minimizing recalls and improving overall product reliability.

Moreover, in the aerospace industry, a fiber marking solution was employed to mark parts with complex serial numbers and barcodes without compromising material integrity. This application not only met the rigorous safety certifications required but also enhanced the overall manufacturing process, yielding a 20% decrease in production downtime. These examples illustrate how fiber marking machines are transforming traditional manufacturing processes, making them more precise, efficient, and responsive to market demands.

Revolutionizing Manufacturing: How Fiber Marking Machines Enhance Precision and Efficiency in Industrial Applications - Case Studies: Success Stories of Fiber Marking in Industrial Applications

| Case Study | Industry | Challenges | Solutions Implemented | Results Achieved |

|---|---|---|---|---|

| Automotive Parts Manufacturer | Automotive | Need for high-precision identification. | Adopted fiber marking machines. | Increased marking accuracy by 30%. |

| Aerospace Components Supplier | Aerospace | Strict regulatory compliance. | Integrated traceability solutions with fiber marking. | Achieved full compliance with traceability standards. |

| Consumer Electronics Brand | Consumer Electronics | Brand identification and differentiation. | Implemented customized fiber marking solutions. | Improved brand visibility and product identification. |

| Medical Device Manufacturer | Biomedical | High standards for safety and identification. | Utilized advanced fiber marking technologies. | Reduced errors in product identification by 40%. |

Future Prospects: Innovations Shaping the Next Generation of Fiber Marking Technology

As industries evolve, the demand for precision and efficiency has never been greater, leading to significant innovations in fiber marking technology. A recent report by MarketsandMarkets forecasts that the global fiber laser market will reach USD 24.3 billion by 2025, driven by the increasing adoption of automation in industrial applications. The latest advancements in fiber marking machines encompass not only improved speed and accuracy but also enhanced user interfaces and integration capabilities with existing manufacturing systems, ensuring a seamless workflow.

In addition to performance boosts, sustainability is a crucial aspect of future innovations. Fiber marking machines utilize less energy compared to traditional methods, aligning with increasing regulatory pressures for eco-friendly practices. According to a study published in the Journal of Cleaner Production, companies that implement greener technologies can reduce operational costs by up to 30%. Furthermore, the scalability of modern fiber marking solutions allows for flexible adjustment to varying production demands, ensuring that manufacturers stay competitive in a rapidly changing marketplace. As the technology continues to advance, we can anticipate a wave of transformative applications that will redefine manufacturing standards globally.

Revolutionizing Manufacturing: Precision and Efficiency of Fiber Marking Machines

This chart illustrates the improvements in precision and efficiency achieved by fiber marking machines in various industrial applications over recent years.