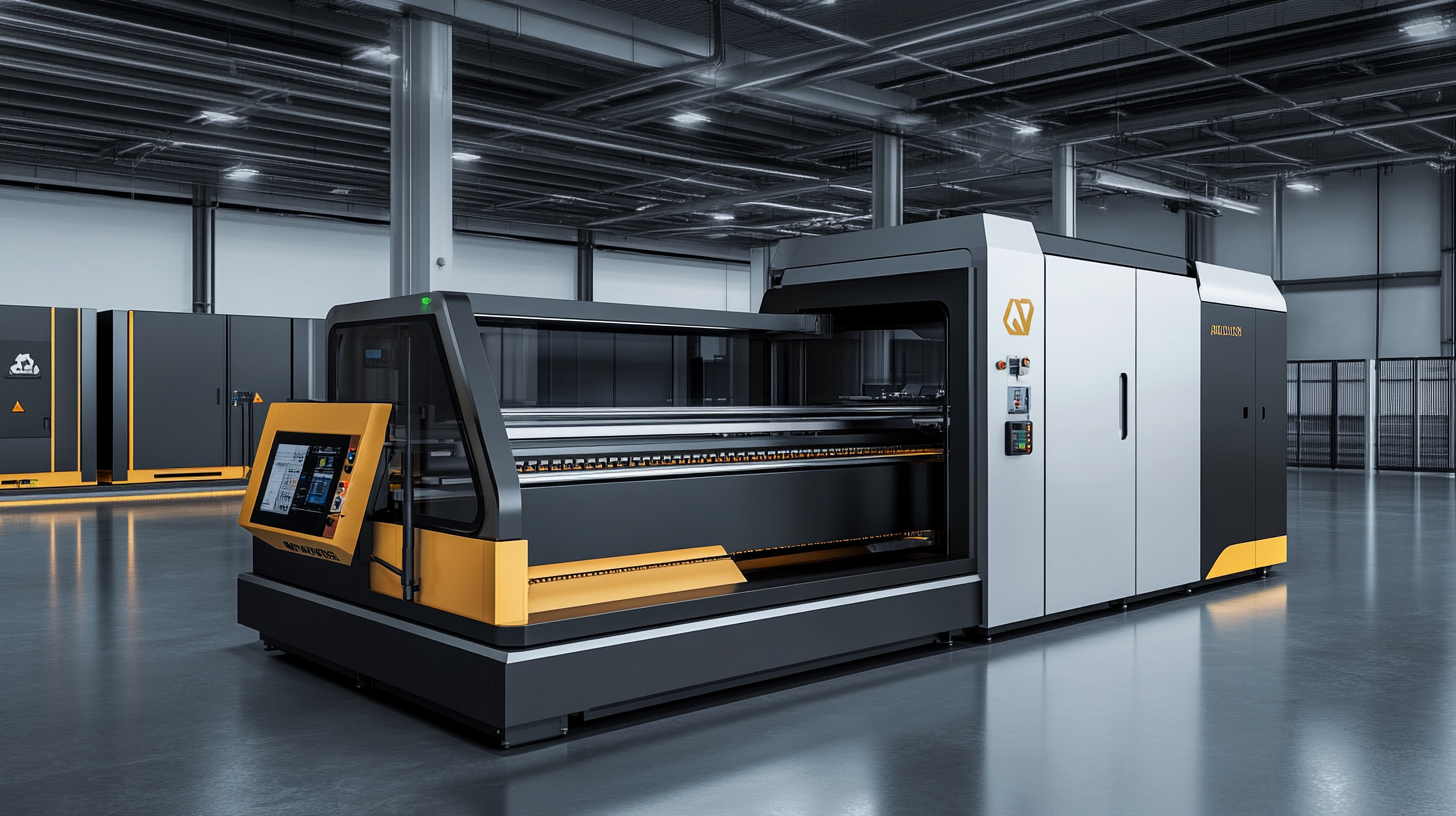

Revolutionizing Production Efficiency with Innovative Fiber Laser Marking Machines

In today's rapidly evolving manufacturing landscape, the pursuit of enhanced production efficiency has become paramount for businesses seeking a competitive edge. One of the groundbreaking advancements in this arena is the Fiber Laser Marking Machine, a powerful tool designed to streamline marking processes and improve overall operational productivity. By utilizing cutting-edge laser technology, these machines offer high precision and versatility, enabling manufacturers to mark a wide variety of materials with exceptional clarity and speed. As companies look for innovative solutions to meet growing demand, understanding the capabilities and benefits of fiber laser marking machinery becomes crucial.

The adoption of Fiber Laser Marking Machines not only enhances the quality of markings but also significantly reduces production times and costs. This revolutionary technology allows for automation in production lines, minimizing manual labor while ensuring consistent results. As we explore the transformative impact of these machines, we will delve into their unique features, applications across various industries, and the ways they can help businesses thrive in a competitive market. The integration of fiber laser marking technology can indeed revolutionize production efficiency, setting new standards for quality and performance in manufacturing processes.

Benefits of Fiber Laser Marking Machines in Modern Manufacturing

In today's fast-paced manufacturing landscape, the adoption of innovative fiber laser marking machines is proving crucial for enhancing production efficiency. With market projections indicating a compound annual growth rate (CAGR) of 7.9%, the global laser marking machine market, valued at approximately USD 2.95 billion in 2022, underscores the increasing reliance on this technology across various sectors. Fiber laser marking machines, in particular, stand out for their ability to produce permanent, high-quality marks on metal surfaces swiftly and cleanly, making them essential tools in modern manufacturing processes. The benefits of fiber laser marking machines extend beyond simple marking capabilities; they enable manufacturers to iterate rapidly and test innovative ideas, which is vital for product development. As industries such as medical device manufacturing integrate these cutting-edge solutions, the impact becomes even more pronounced. Laser materials processing systems are becoming pivotal in creating precise markings on devices like cardiac implants and orthopedic tools, enhancing traceability and compliance with regulatory standards. Investing in advanced laser marking technology not only optimizes manufacturing facilities but also improves the overall finish and geometry of produced items. Companies are now recognizing that the efficiency and quality that fiber laser marking systems bring can lead to significant competitive advantages, affirming their importance in the evolution of modern manufacturing practices. As businesses navigate the next wave of growth, integrating these advanced systems is set to be a game-changer in their production strategies.

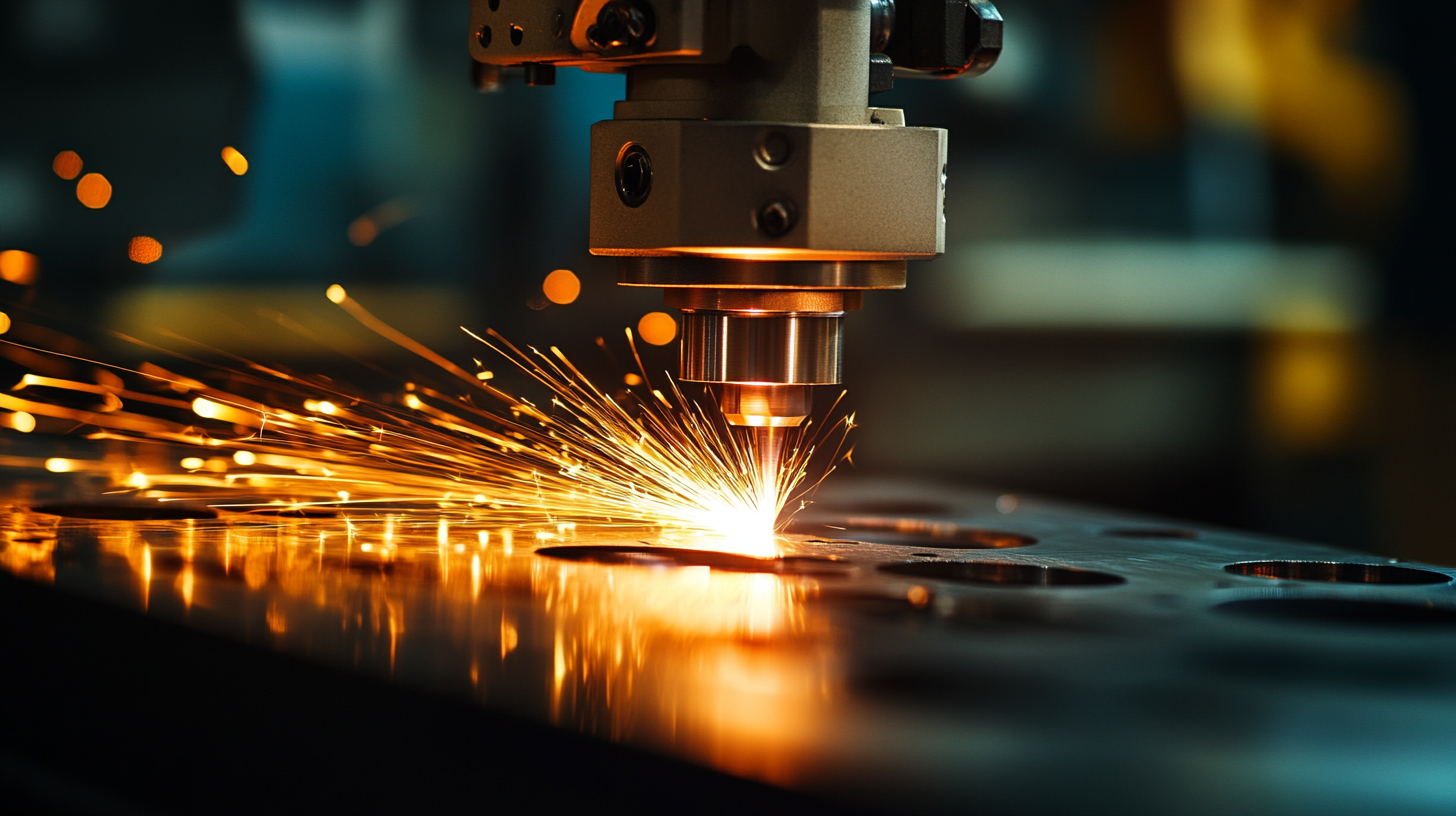

How Fiber Laser Technology Enhances Precision and Quality in Marking

Fiber laser technology is revolutionizing the way industries approach precision and quality in marking applications. With the global laser marking machine market projected to grow at a compound annual growth rate (CAGR) of 7.9%, reaching an estimated value of USD 2.95 billion by 2022, the demand for innovative solutions continues to surge. Fiber laser marking machines, particularly the newly introduced 200W model, exemplify the cutting-edge capabilities that modern manufacturing requires.

One of the key advantages of fiber laser marking is its unparalleled precision. The technology utilizes a concentrated beam of light that allows for intricate designs and markings on various materials, including metals and plastics. This level of accuracy not only enhances the visual appeal of products but also plays a crucial role in ensuring traceability and compliance within regulated industries such as aerospace and automotive. As noted in recent advancements, femtosecond laser technology is opening new avenues for application, pushing the boundaries of what's possible in marking.

Moreover, the sleek design of modern fiber laser marking machines makes them highly efficient in production environments. Their ability to operate at high speeds while maintaining consistent quality means that manufacturers can increase their output without compromising on the durability or precision of markings. The integration of robotics and automation further streamlines processes, as evidenced by the anticipated growth in the automated laser marking machine market, which is also expected to gain traction across various sectors. As industries look to enhance their production efficiency, fiber laser technology stands out as a vital tool in achieving both excellence and innovation.

Cost Efficiency: Reducing Operational Expenses with Fiber Laser Solutions

The advent of fiber laser marking machines marks a significant evolution in the quest for cost efficiency in production environments. These machines leverage innovative technology to minimize operational expenses while enhancing precision and speed. As industries increasingly recognize the advantages of fiber lasers over traditional CO2 lasers, the shift towards these cutting-edge solutions is transforming the landscape of manufacturing. The penetration of fiber laser cutting systems has surged dramatically, with sales figures demonstrating a clear preference for fiber technology, thanks to its superior power efficiency and lower running costs.

In particular, fiber laser marking machines have revolutionized how businesses approach their production processes. Their ability to deliver high-quality markings with reduced maintenance and energy consumption translates directly to lower operational expenses. Companies stand to benefit not only from decreased costs but also from improved product quality and increased throughput. This synergy of cost-cutting and performance enhancement makes fiber laser solutions an attractive proposition for various industries, including automotive, electrical, and medical fields. As manufacturers pivot towards these advanced technologies, the potential for significant savings and efficiency gains becomes increasingly apparent.

Applications of Fiber Laser Marking Across Various Industries

The application of fiber laser marking machines has seen a remarkable upsurge across various industries, fundamentally transforming production efficiency and product quality. The global laser marking machine market is projected to exceed USD 5.8 billion by 2032, growing at a CAGR of 7.5%, up from USD 2.8 billion in 2022. This growth is driven by the increasing demand for precision and speed in marking processes—requirements that fiber laser technology readily meets through its higher energy efficiency and rapid processing capabilities.

In sectors such as packaging and manufacturing, the benefits of fiber laser marking are particularly pronounced. These systems are lauded for their ability to provide clean and permanent markings on diverse materials, including metals and plastics, essential for product identification and traceability. For instance, the latest innovations have made it feasible to integrate compact laser marking heads into production lines, enhancing workflow without compromising space or efficiency.

Furthermore, detailed studies indicate that the ability to create textured surfaces through laser marking significantly enhances the physical, chemical, and biological properties of various products. This versatility not only elevates the functional attributes of items, such as precision gears but also boosts their aesthetic appeal, enriching consumer experience and satisfaction. As industries continue to adapt to the growing technological landscape, fiber laser marking stands out as a pivotal solution, effectively bridging the gap between operational efficiency and product excellence.

Future Trends in Fiber Laser Marking Technologies and Their Impact on Production

The evolution of fiber laser marking technologies is significantly reshaping production processes across various industries, particularly in the packaging sector. Recent reports indicate that the global laser marking equipment market is projected to expand by USD 1,226.21 million from 2022 to 2027, driven primarily by the increasing demand for coding and marking applications. This growth underscores the critical role that innovative marking solutions play in enhancing production efficiency while ensuring compliance with regulatory standards.

As businesses strive to optimize their operations, the adoption of fiber laser marking machines stands out as a transformative trend. These machines offer unparalleled precision and speed, making them ideal for high-volume production environments. The industrial laser market, valued at approximately USD 17.29 billion in 2020, highlights the significant investment being made in advanced laser technologies. The shift towards fiber lasers, known for their superior energy efficiency and lower operational costs compared to traditional laser systems, is making a profound impact on manufacturing strategies.

Moreover, the ongoing innovation in fiber laser marking technologies is set to revolutionize how products are identified and authenticated. As industries increasingly prioritize automation and smart manufacturing solutions, fiber laser systems are becoming integral components of the production line, enhancing not just efficiency but also product traceability. The future of fiber laser marking is promising, as it continues to align with the demand for sustainability and cost-effective production methodologies in an ever-evolving marketplace.