12 Innovative Ways Fiber Laser Marking Machines Revolutionize Manufacturing Today

In today's fast-evolving manufacturing landscape, the adoption of advanced technologies is pivotal for enhancing productivity and precision. Among these innovations, the Fiber Laser Marking Machine has emerged as a game-changer, offering unparalleled advantages in marking and engraving applications across various industries. According to a report by Markets and Markets, the global laser marking market is projected to grow from $2.2 billion in 2020 to $3.8 billion by 2025, showcasing a CAGR of 11.5%. This surge is largely attributed to the efficiency, speed, and versatility of fiber laser technology, which allows manufacturers to produce high-quality markings with minimal downtime. By harnessing the power of fiber lasers, businesses can streamline operations, reduce costs, and enhance product traceability, fundamentally transforming the manufacturing process in ways previously unimagined.

The Evolution of Fiber Laser Marking Technology in Modern Manufacturing

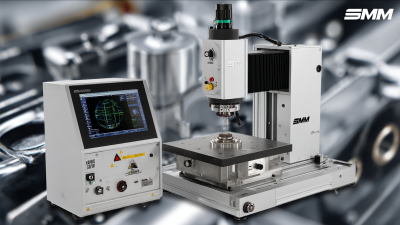

The evolution of fiber laser marking technology has significantly transformed modern manufacturing, paving the way for increased precision and efficiency. Unlike traditional marking methods, fiber lasers utilize advanced optics to produce high-quality marks on a variety of materials without compromising their integrity. This innovation enables manufacturers to meet stringent quality standards while also catering to the growing demand for customized products. As industries shift towards more automated processes, fiber laser marking machines emerge as essential tools that streamline production lines and reduce downtime.

When considering the implementation of fiber laser marking machines, manufacturers should keep in mind a few key tips. First, assess the materials you will be marking; fiber lasers are especially effective on metals and certain plastics, so ensure your products are compatible. Next, invest in training for your operators; understanding the technology will enhance efficiency and ensure that safety protocols are followed correctly. Lastly, integrate these machines within a broader strategy for automation—this will not only improve productivity but also facilitate the transition toward a smarter, more interconnected manufacturing environment.

Key Benefits of Fiber Laser Marking Machines Over Traditional Methods

Fiber laser marking machines have transformed the manufacturing landscape, offering significant advantages over traditional marking methods. One of the key benefits is their precision. Fiber lasers deliver intricate designs and markings with unparalleled accuracy, which is essential for modern industries that require detailed identification, such as in automotive and electronics. This precision not only enhances product quality but also reduces waste, as fewer errors mean less time and resources spent on corrections.

Moreover, fiber laser marking is faster than conventional methods. With the ability to mark materials quickly and efficiently, manufacturers can significantly boost their productivity. This speed is particularly beneficial in high-volume production environments, where time is critical. Furthermore, these machines are low-maintenance and have a longer lifespan compared to traditional marking equipment, resulting in lower operational costs.

Tip: When integrating fiber laser marking into your production line, ensure that your staff receives adequate training. Understanding the machine's capabilities and maintenance requirements can lead to optimal performance and improved output quality. Additionally, consider the types of materials you will be working with, as different materials may require specific laser settings for the best results.

Impact of Fiber Laser Marking Machines in Manufacturing

Impact of Fiber Laser Marking on Production Efficiency and Cost Reduction

Fiber laser marking machines are reshaping manufacturing by significantly enhancing production efficiency. Unlike traditional marking methods, fiber lasers provide precise and permanent markings on a variety of materials, reducing the need for time-consuming setups and adjustments. This precision leads to faster production lines, as manufacturers can mark parts in a matter of seconds without compromising quality. The ability to automate the marking process further streamlines operations, allowing for higher throughput and minimal human intervention, which is crucial in high-volume production environments.

Cost reduction is another significant benefit of fiber laser marking technology. These machines are known for their energy efficiency and low maintenance requirements compared to older marking solutions, translating into lower operational costs over time. Furthermore, the durability of the marks eliminates the need for repainting or application of labels, leading to a decrease in material costs. By investing in fiber laser marking systems, manufacturers not only improve their output but also create a more sustainable operation, ultimately resulting in a competitive edge in today's fast-paced marketplace.

Case Studies: Successful Implementation of Fiber Laser Marking in Various Industries

Fiber laser marking machines have emerged as transformative tools across various industries, streamlining manufacturing processes with their precision and efficiency. A compelling case study comes from the automotive industry, where a leading manufacturer integrated fiber laser marking to trace components throughout production. This implementation not only improved quality control and traceability but also reduced the time spent on manual labeling, resulting in significant cost savings and enhanced operational efficiency.

In the aerospace sector, another success story highlights how fiber laser marking has revolutionized part identification. A major aerospace company adopted this technology to mark intricate serial numbers and barcodes directly onto engine components. The durability of fiber laser markings, which withstand extreme conditions, ensured compliance with stringent regulations. Moreover, the quick turnaround time for marking operations minimized downtime, allowing for a more agile manufacturing environment. Such innovative uses of fiber laser marking machines exemplify their impact on enhancing productivity and compliance across diverse industries.

Future Trends: How Fiber Laser Marking Machines are Shaping Manufacturing Practices

The integration of fiber laser marking machines into manufacturing processes represents a significant shift in operational efficiency and versatility. As part of the larger trend towards Industry 4.0, these innovations capitalize on advanced technologies that enhance precision and reduce downtime. By leveraging fiber lasers, manufacturers can achieve high-speed marking with exceptional detail, making it possible to customize products in ways that were previously unforeseen. This adaptability not only improves production workflows but also meets the growing demand for personalized goods.

Looking ahead, fiber laser marking machines are set to shape future manufacturing practices through their ability to integrate seamlessly with automation systems and data-driven processes. As factories become increasingly interconnected, the capability of fiber lasers to provide real-time feedback and adjust operations accordingly will redefine quality control standards. Furthermore, ongoing advancements in laser technology promise to expand their applications, driving further innovation in sectors from automotive to electronics. The rise of smart factories heralds a new age of manufacturing, where fiber laser technology is at the forefront of efficiency and customization.

12 Innovative Ways Fiber Laser Marking Machines Revolutionize Manufacturing Today

| Application | Industry Impact | Benefits | Future Trends |

|---|---|---|---|

| Personalization of Products | Consumer Goods | Enhanced Customer Engagement | Increased demand for custom designs |

| Tracking and Identification | Automotive | Improved Supply Chain Management | Integration with IoT technologies |

| Permanent Marking of Components | Aerospace | Enhanced Product Traceability | Legislation compliance on traceability |

| Processing of Complex Designs | Electronics | Higher Accuracy in Production | Innovation in product designs |

| Surface Treatment | Medical | Increased Durability of Products | Advancements in biocompatible materials |

| Fast Prototyping | Manufacturing | Reduced Time to Market | Shift towards agile manufacturing processes |

| Eco-Friendly Processes | Packaging | Sustainability Acknowledgment | Growth in sustainable packaging solutions |

| Shorter Setup Times | Textiles | Increased Operational Efficiency | Automation integration in textile processing |

| Reduction of Waste | Furniture | Cost Savings | Focus on circular economy practices |

| High-Precision Marking | Jewelry | Branding Enhancement | Customization trends in high-value items |

| Increased Automation | Construction | Improved Labor Efficiency | Future growth in automated construction tech |

| Remote Monitoring | Electronics | Enhanced Operational Oversight | Expansion of Industry 4.0 initiatives |

Related Posts

-

10 Ways Best Laser Part Marking Improves Productivity by 30 Percent

-

Advantages of Using Fiber Marking Machines for Global Procurement

-

Future Trends in Fiber Marking Machines How Automation Will Shape Industry Standards by 2025

-

Revolutionizing Manufacturing: How Fiber Marking Machines Enhance Precision and Efficiency in Industrial Applications

-

5 Essential Tips for Choosing the Best Laser Part Marking Machine for Your Business

-

Expert Guide: Mastering Handheld Dot Peen Marking Machines for Precision Manufacturing