What is stainless steel wire mesh and its uses?

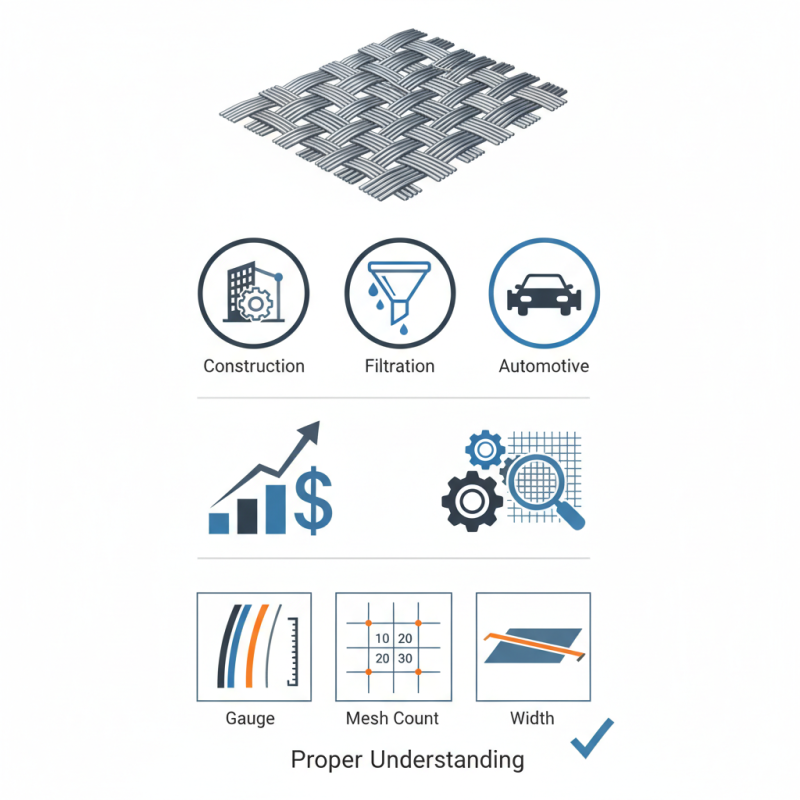

stainless steel wire mesh is a versatile material widely used in various industries. Its corrosion resistance and strength make it ideal for construction, filtration, and automotive applications. According to a recent report by MarketsandMarkets, the global stainless steel wire mesh market is projected to reach USD 3.2 billion by 2027, reflecting its growing importance.

Industry expert John Smith stated, “stainless steel wire mesh not only enhances durability but also improves efficiency in many industrial applications.” This highlights the mesh's significance in modern manufacturing. However, while its benefits are clear, some users may overlook the importance of choosing the right specifications for their needs.

Inadequate knowledge about wire types and weaving techniques can lead to suboptimal performance. For efficient use, factors like gauge, mesh count, and width must be carefully considered. Potential users should reflect on these aspects to avoid pitfalls. Proper understanding can enhance the effectiveness and longevity of stainless steel wire mesh in any application.

Definition and Composition of Stainless Steel Wire Mesh

Stainless steel wire mesh is a versatile material. It is made from stainless steel, which provides excellent resistance to rust and corrosion. This composition makes it suitable for various applications. The key elements include iron, chromium, and nickel. The chromium gives it rust-resisting properties. Nickel adds strength and durability.

The structure of stainless steel wire mesh consists of interwoven wires. These wires can vary in diameter and spacing. This variation allows customization for specific needs. Many industries benefit from this material. For example, in construction, it is used for reinforcement. In agriculture, it serves as fencing or for sifting soil. However, the mesh might not always be strong enough for heavy-duty applications.

While stainless steel wire mesh is reliable, it has limitations. The cost can be higher than alternative materials. Poor installation can lead to problems, such as rust over time. There is also the challenge of cleaning, as debris can get trapped in the mesh. It's important to assess these factors when choosing this material for a project.

Types of Stainless Steel Wire Mesh and Their Characteristics

Stainless steel wire mesh is widely used in various industries. It comes in different types, each with unique characteristics. The most common types include woven mesh, welded mesh, and perforated mesh. Each type serves specific purposes based on its structure.

Welded mesh consists of wires that are welded at intersections. It offers a rigid structure, making it suitable for security applications. On the downside, the welds can sometimes weaken over time with exposure to corrosive elements.

These variations highlight the need to choose the right type of stainless steel wire mesh based on specific needs and environments. Using the right type can prevent future issues and ensure longevity.

Common Applications of Stainless Steel Wire Mesh in Various Industries

Stainless steel wire mesh is a versatile material used across many industries. Its durability and resistance to corrosion make it ideal for various applications. In construction, it strengthens concrete and helps in preventing soil erosion. The mesh can also be seen in architectural designs, providing aesthetic appeal while offering functional benefits.

Food processing companies rely on stainless steel wire mesh for safe and clean filtration. It is used to create barriers, preventing contamination. In the pharmaceutical industry, this mesh assists in maintaining sterile environments. The fine openings allow for efficient air and fluid flow, which is crucial in cleanrooms. Yet, it’s important to ensure that the mesh meets industry standards.

Another noteworthy application is in agriculture. Farmers utilize it for fencing, crop protection, and pest control. The strength of the mesh is vital in deterring animals from damaging crops. Sometimes, however, the mesh may corrode if not properly treated or maintained. Regular inspection is key to maintaining its performance. Each use case highlights the need for attention to detail.

Benefits of Using Stainless Steel Wire Mesh Over Other Materials

Stainless steel wire mesh is a versatile material. It has many applications in various industries. Its strength and durability make it a popular choice for filtration and reinforcement. Unlike other materials, stainless steel does not rust easily. This property is crucial for outdoor applications, such as fencing or architectural designs.

One major benefit of using stainless steel wire mesh is its resistance to corrosion. This allows it to last longer in harsh environments. Compared to plastic or mild steel, stainless steel withstands extreme temperatures and chemicals. This reliability saves costs in the long run. However, it can be more expensive upfront. The initial investment may deter some buyers.

Another advantage is the aesthetic appeal of stainless steel. It offers a modern look in design applications. Yet, some might find it too industrial for certain spaces. Balancing functionality with aesthetics can be challenging. This complexity requires thoughtful consideration when choosing materials for projects.

What is stainless steel wire mesh and its uses? - Benefits of Using Stainless Steel Wire Mesh Over Other Materials

| Dimension | Application | Benefits | Comparison with Other Materials |

|---|---|---|---|

| 1/4 inch | Filtration | Corrosion resistance | More durable than plastic |

| 1/2 inch | Cages and enclosures | Strength and stability | Less prone to physical damage than wood |

| 3/4 inch | Architecture and design | Aesthetic appeal | Does not rust compared to iron |

| 1 inch | Industrial applications | Long lifespan | More resistant to chemicals than aluminum |

Maintenance and Care Tips for Stainless Steel Wire Mesh Products

Stainless steel wire mesh is widely used for various applications. However, proper maintenance is crucial for its longevity. Regular cleaning is essential. You can use mild soap and warm water for this task. A soft cloth or sponge works best. Be sure to rinse it thoroughly. This helps prevent corrosion and staining.

Inspect the wire mesh frequently. Look for signs of wear or damage. If you notice rust spots, treat them immediately. Using a rust remover can help restore the mesh. It’s easy to overlook these details. But neglect can lead to larger issues.

Avoid placing the mesh in areas with high humidity. This can accelerate rust formation. If you’re storing it, keep it in a dry environment. Regularly applying a protective coating can enhance its durability. Think of the mesh as an investment. Treat it well, and it will serve you for years. Remember, small actions lead to great outcomes.